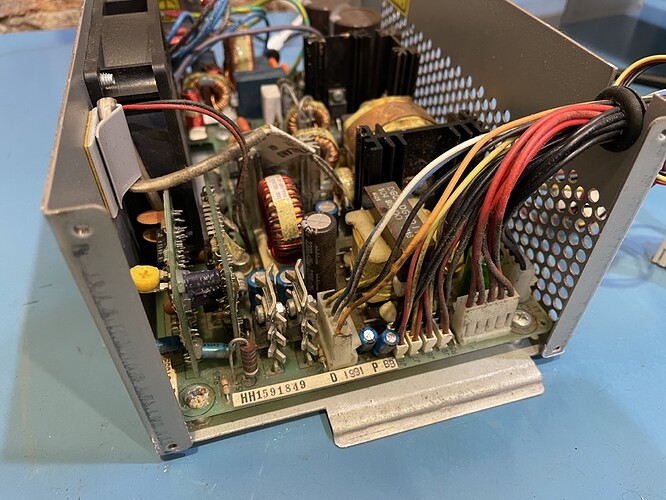

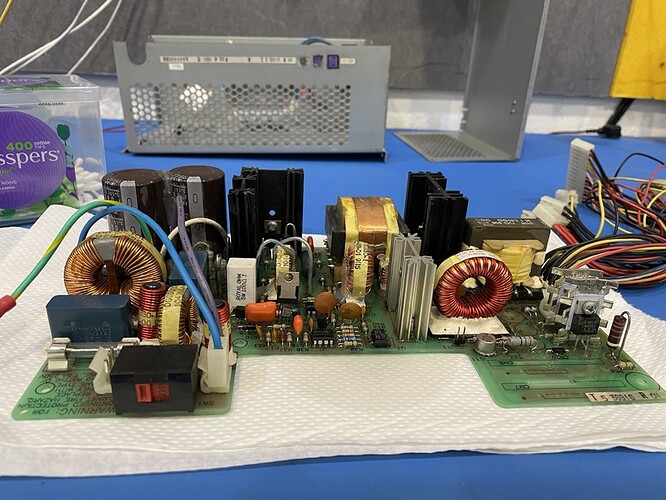

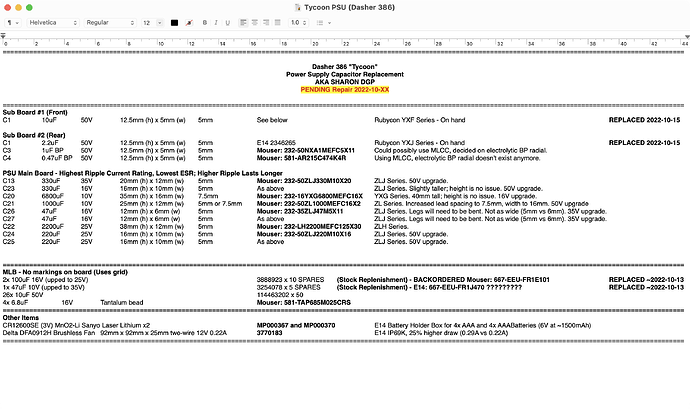

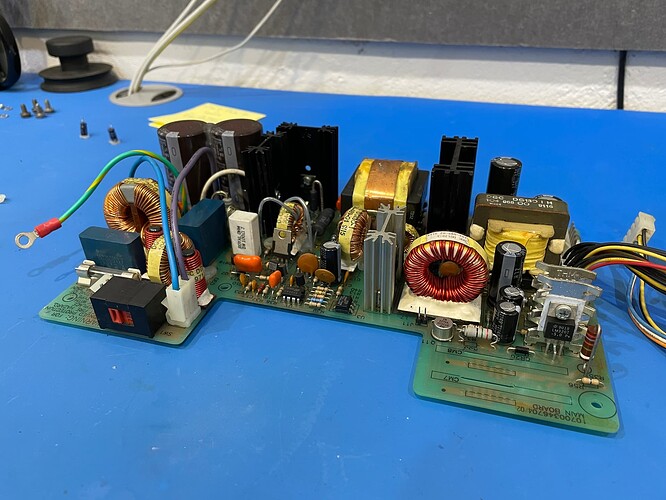

Here’s the work-in-progress capacitor list. It’s mostly complete at this stage and the order has been placed with Mouser. Why Mouser? They have stock of what I want. Usually, I’d opt for Element 14 which is a little more local. Unfortunately their stocks are low or backordered for almost everything I wanted. Mouser seems to have all the parts needed to complete the job.

One of my rules is always to pick the higher quality capacitors or brands with a bit more reputation behind them. Some brands had issues in the early 2000s, and not just with the capacitor plague. As a result, I tend to stick with Rubycon and Panasonic capacitors.

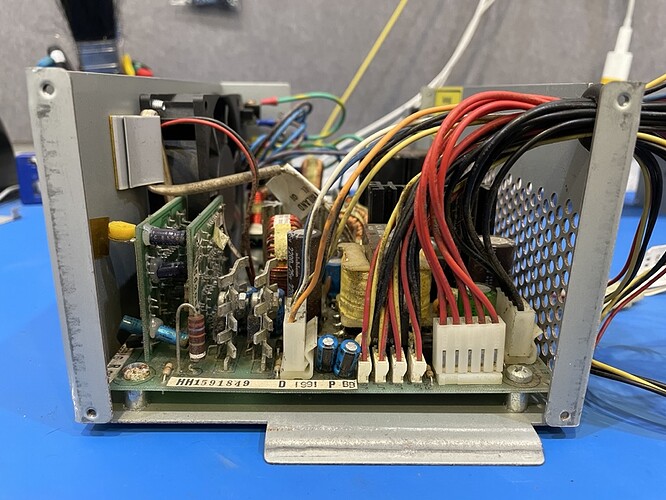

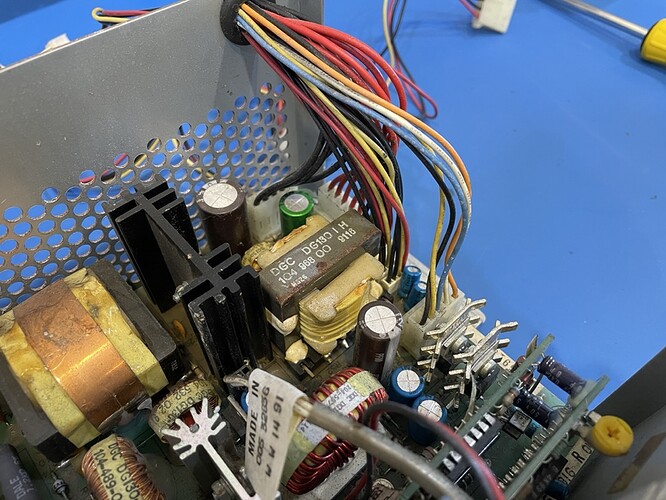

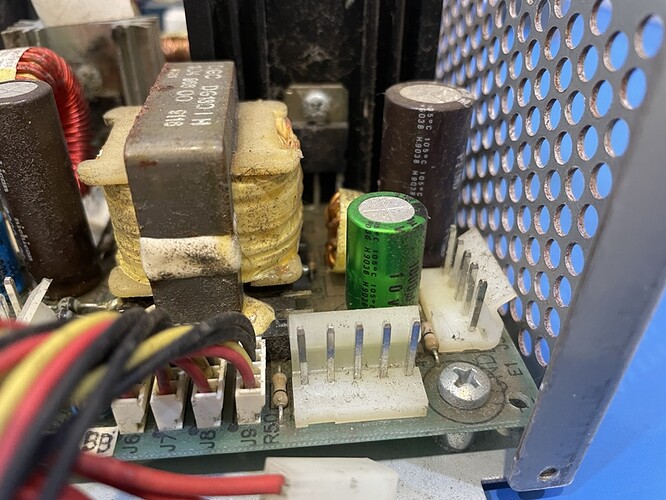

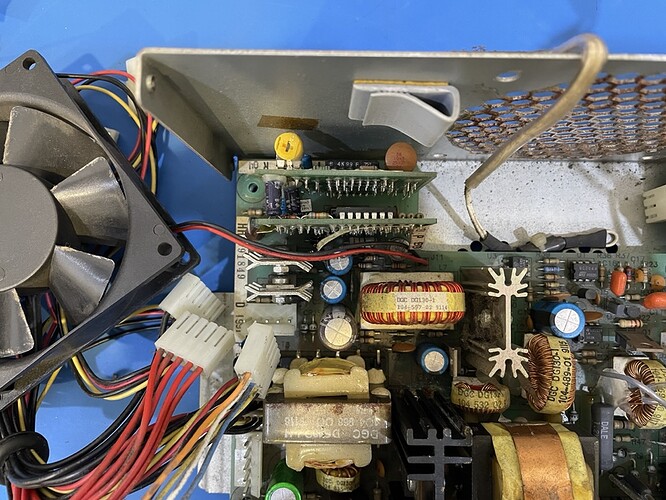

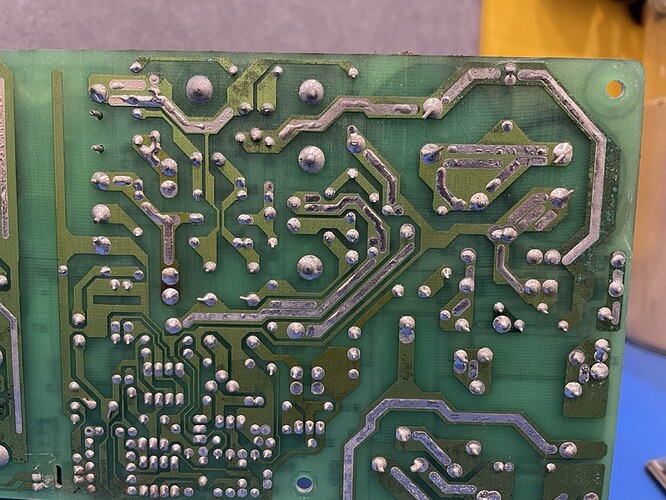

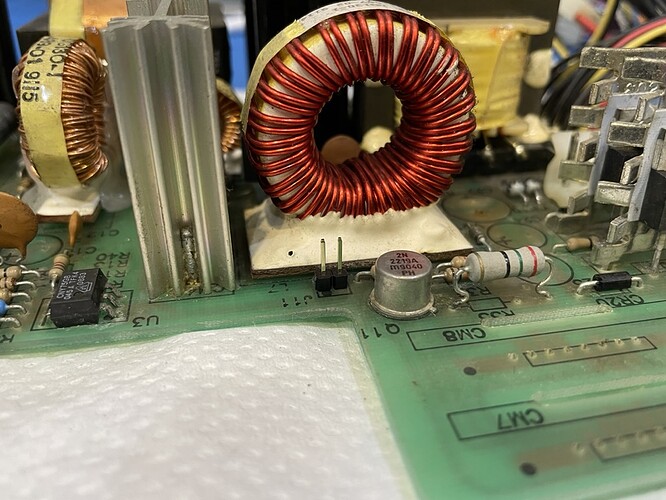

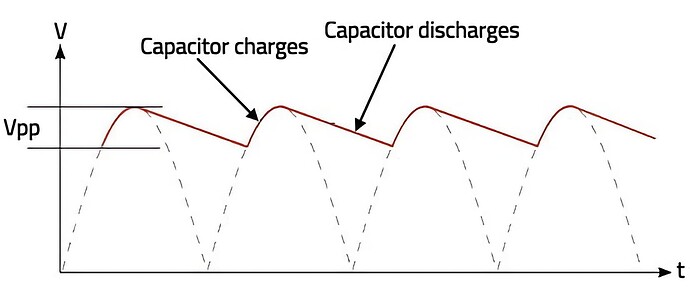

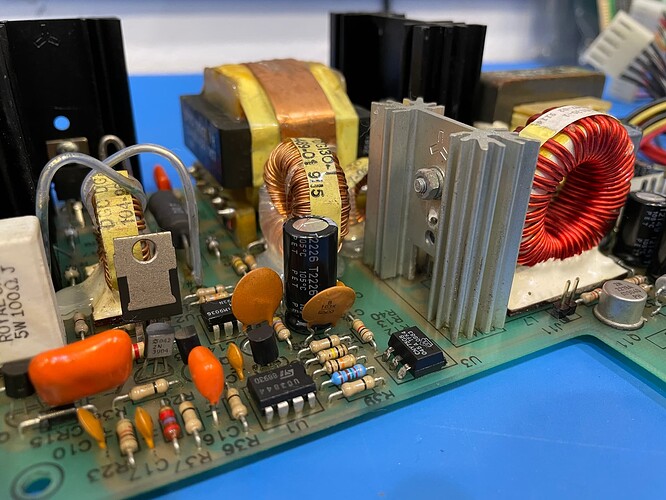

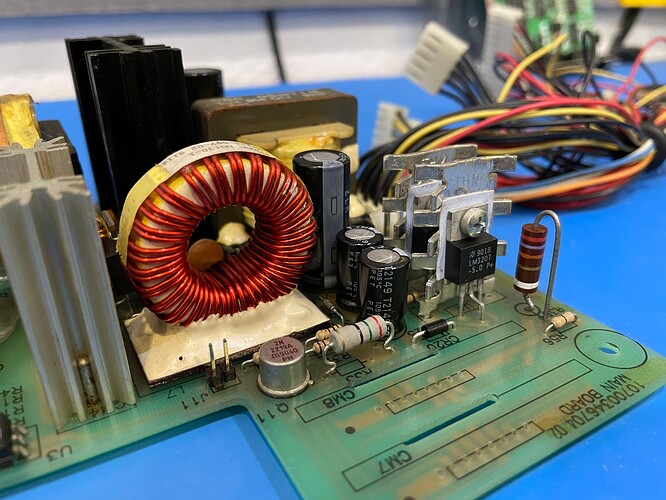

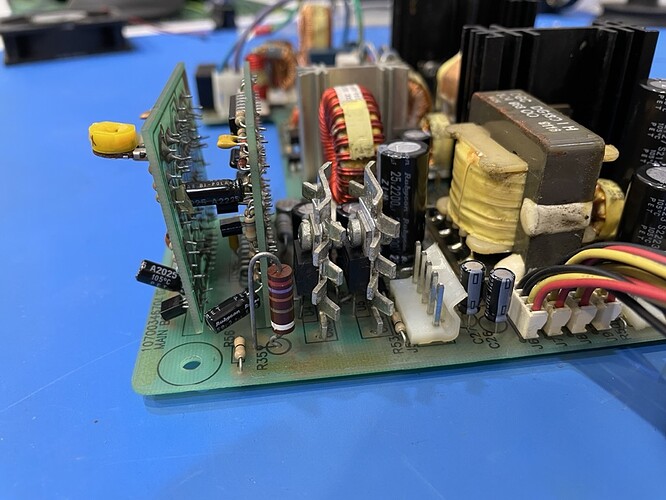

I’ve learned a thing or two while looking into this project. One of those is that in the power supply area, you want low ESR/high ripple current/low impedance capacitors. As I understand it, the oscillations of operating on AC can make components vibrate (or ripple) generating heat, capacitors are prone to this. This heat eventually will cause the ESR to increase as the capacitor electrolyte dries out. We reduce this in power supplies by using low ESR, high impedance with a high ripple current rating.

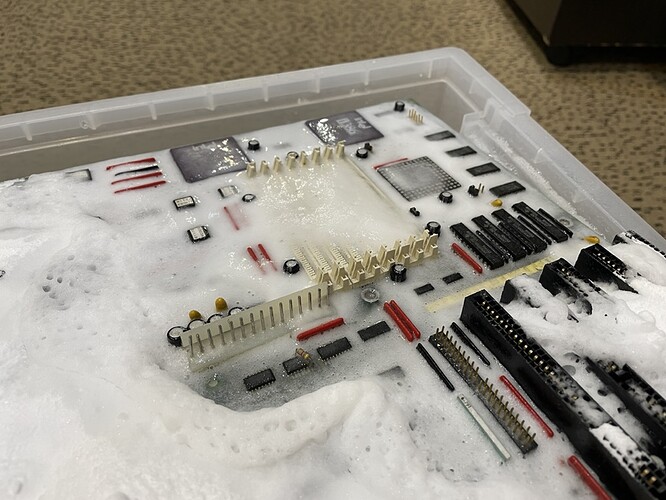

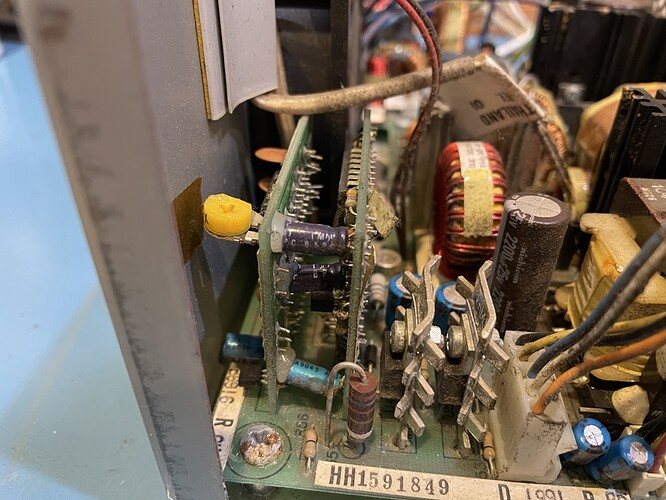

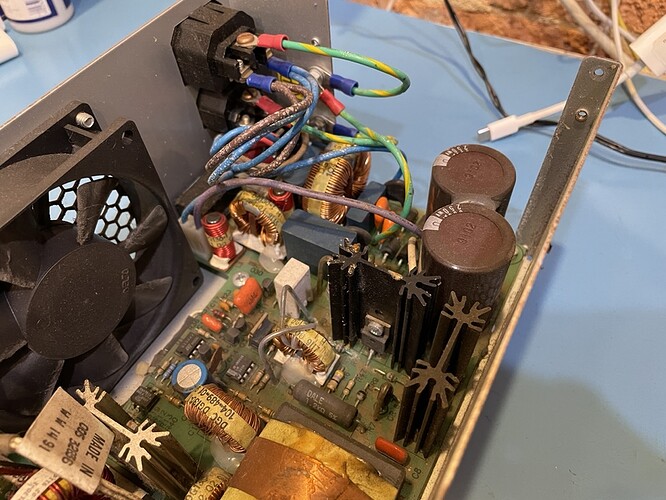

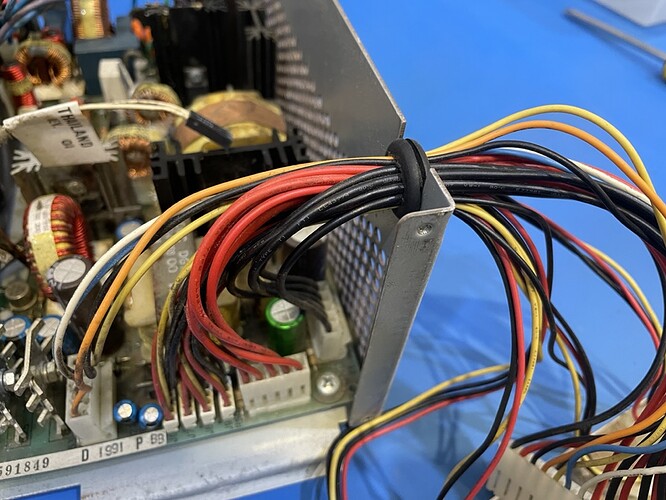

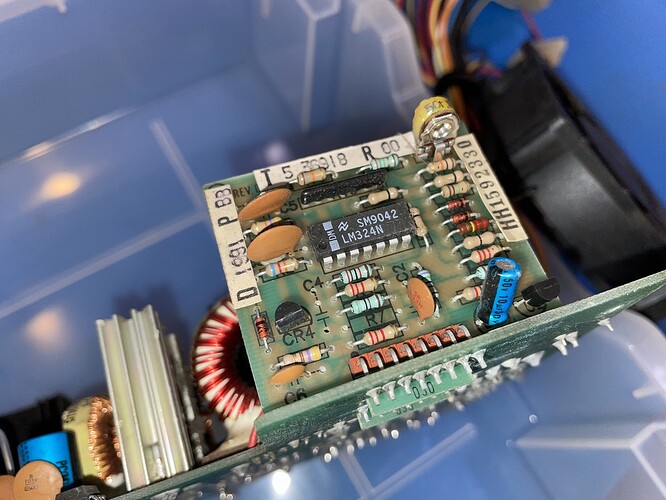

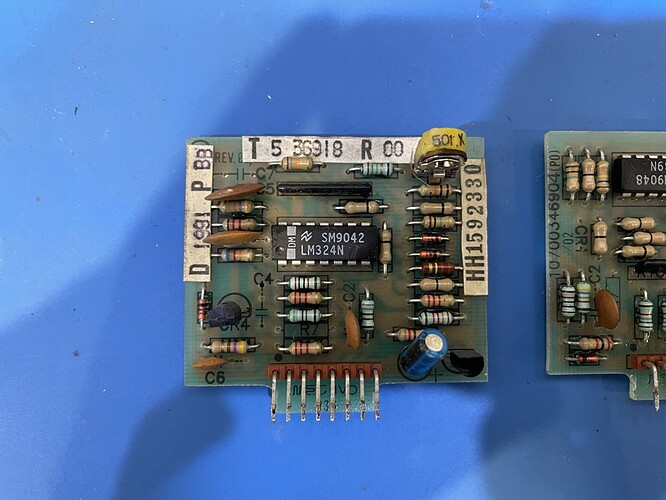

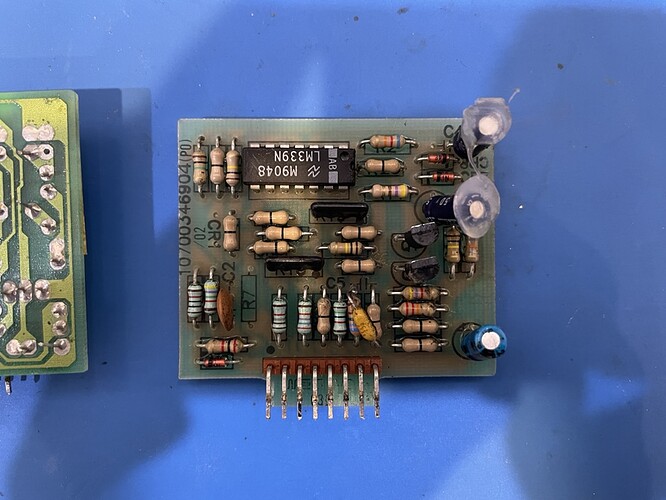

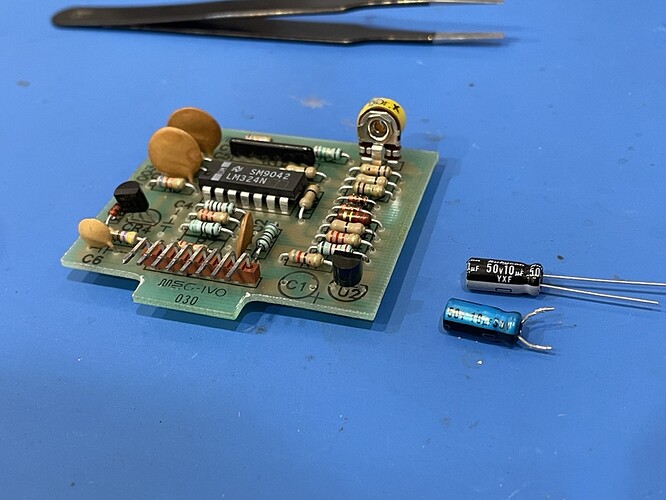

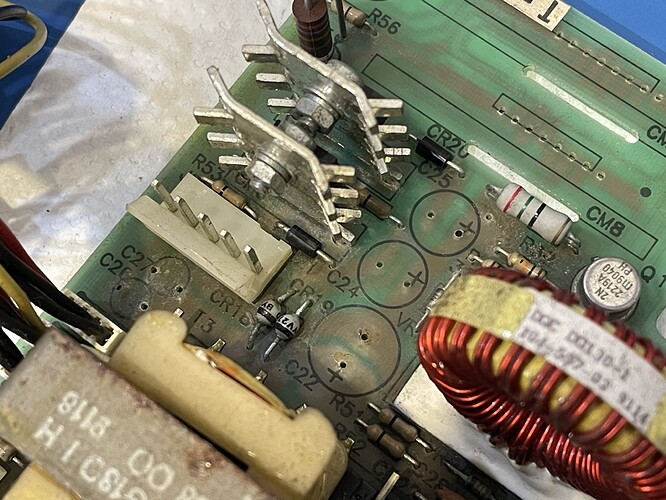

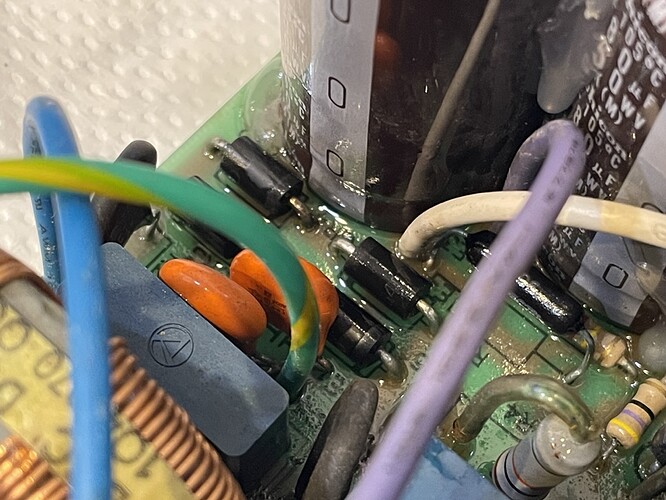

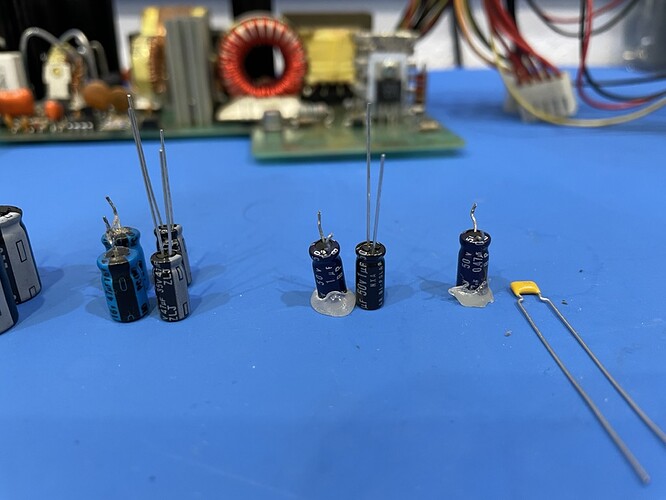

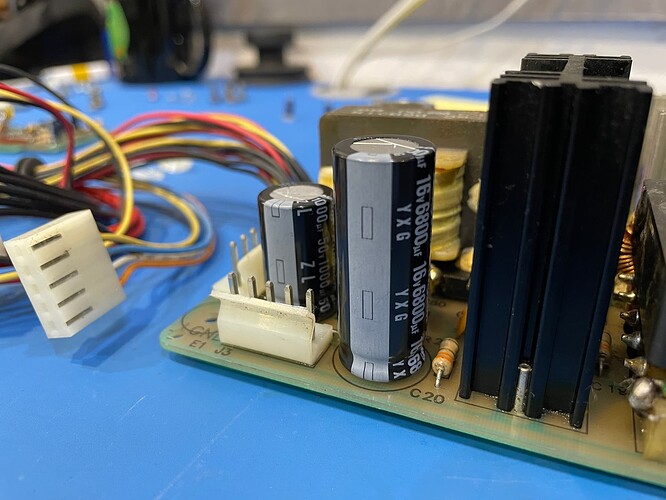

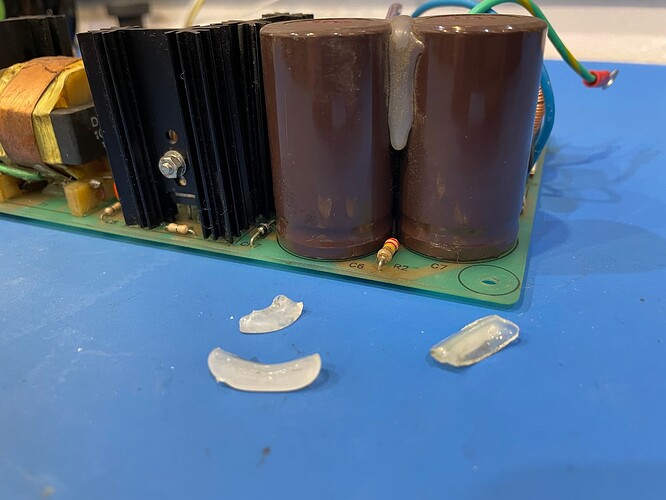

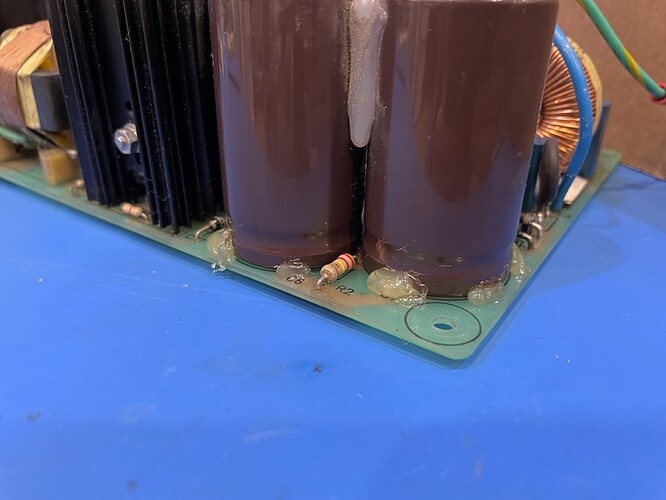

You can see the size difference in the originals compared to the potential replacements I decided against. With the excess ripple, it leads to a capacitor that will get hot, reducing lifespan.

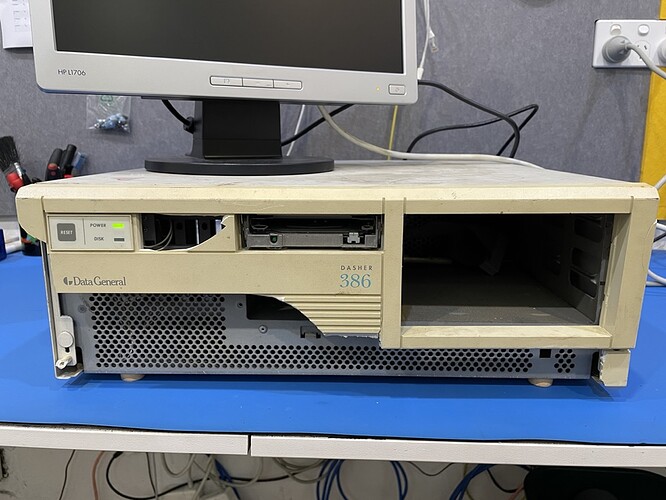

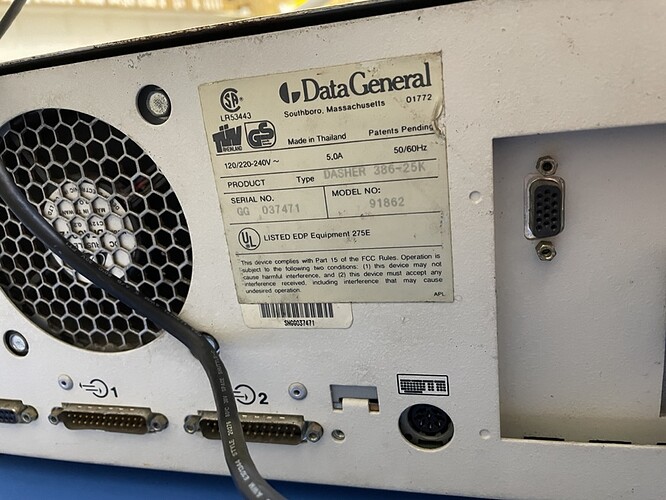

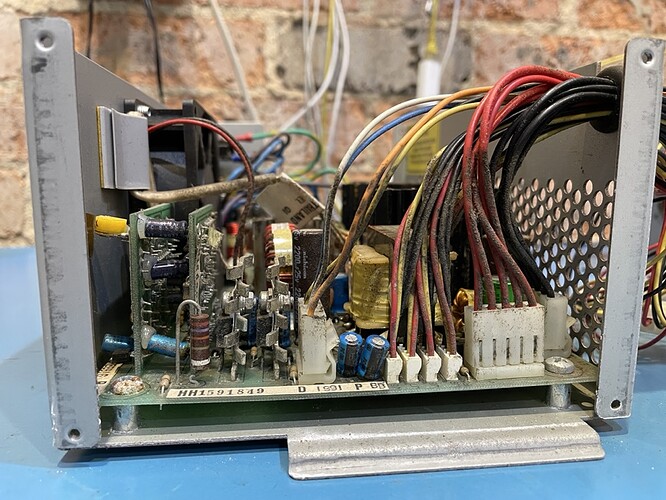

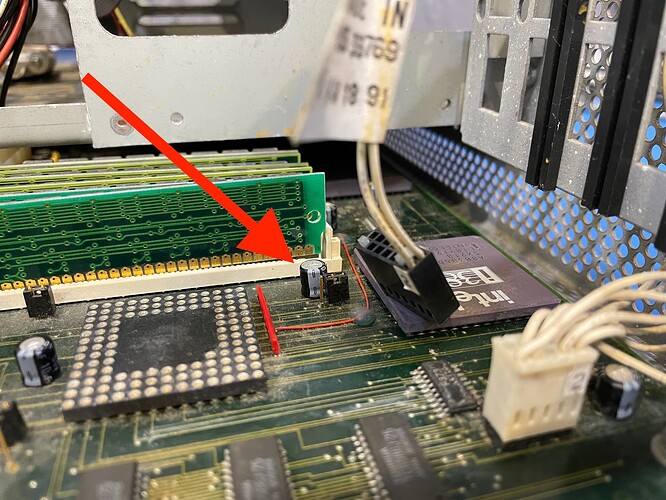

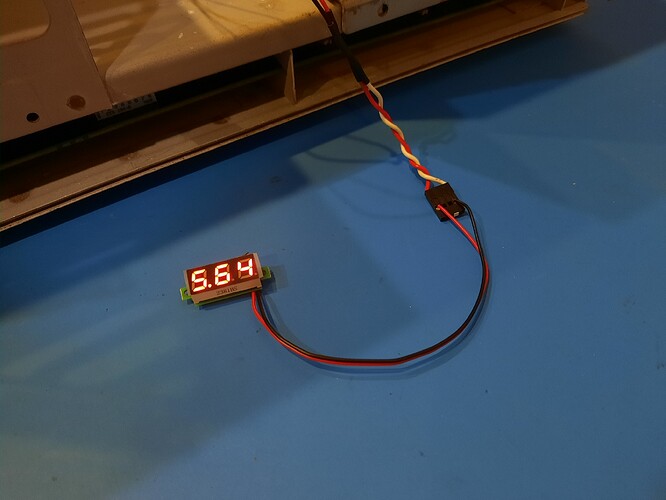

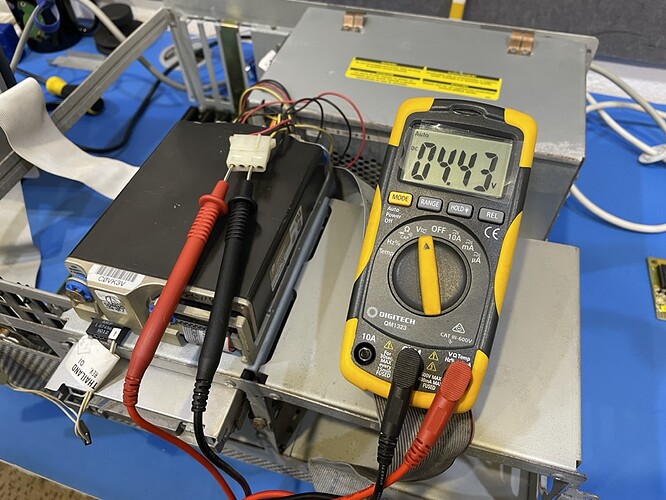

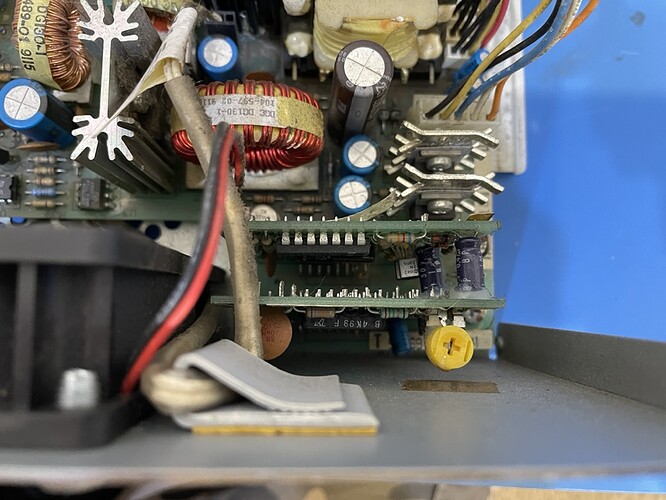

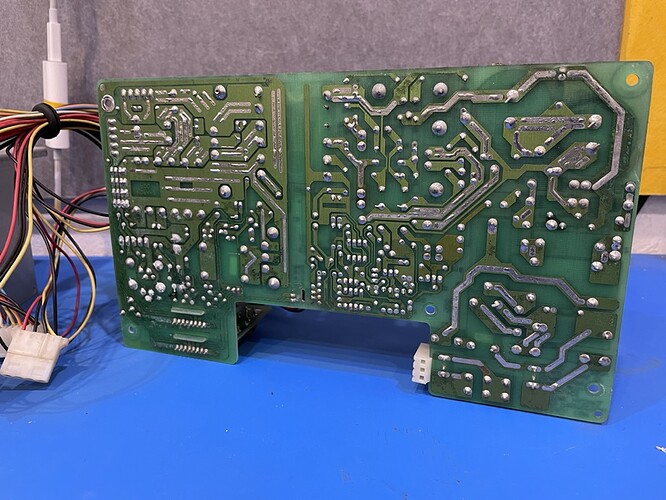

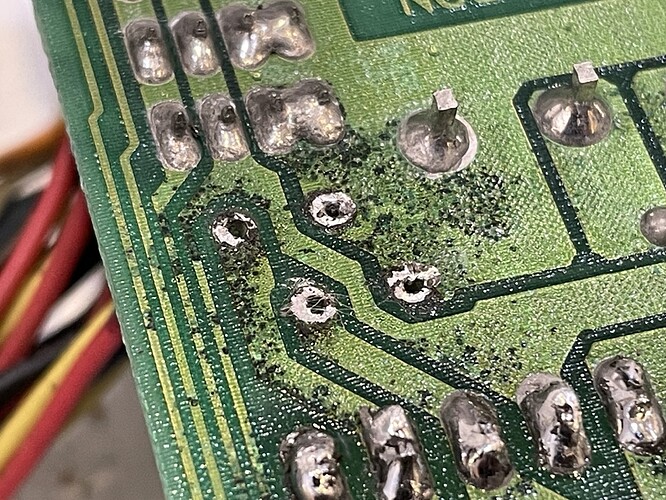

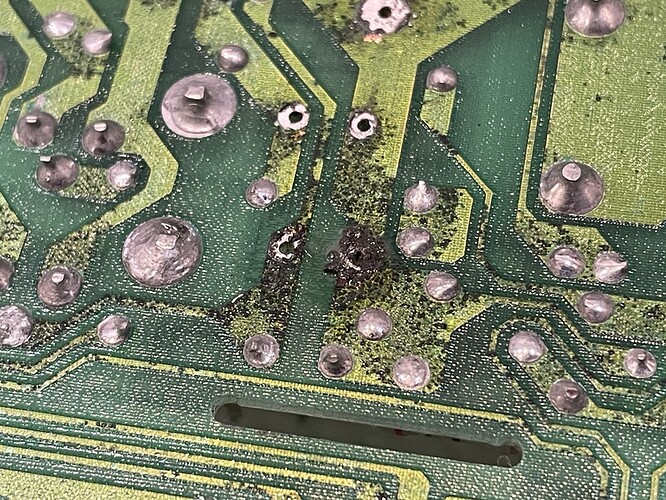

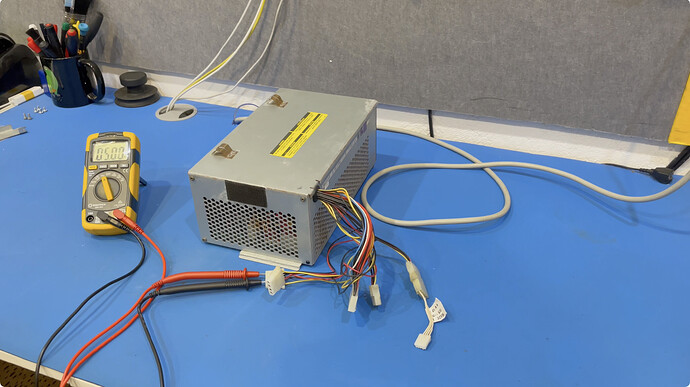

The theory we are working with on the no POST fault of this PC is that the capacitors in the power supply have an ESR that is too high. This allows noise to be introduced into the circuit. That noise is what I believe to be causing the power good signal to not be generated in time by the power supply - and probably that low +5V rail.

Remember we are only dealing with electrolytic capacitors in this project. We want to match, or exceed (see notes below) the old capacitors in at least these key areas when dealing with an AC mains power supply:

- Capacitance

- Voltage

- Physical Size

- Ripple Current Rating

- Temperature

Capacitance

Match this with the value as close as you can. Most capacitors have a ±20% rating which may allow some movement in values but I have not had to ever change this. I would recommend that you don’t either.

Voltage

Increasing the voltage will increase the ripple current rating. Rubycon and Panasonic miniaturise their capacitors, often at the cost of the ripple current rating. Selecting a higher voltage will increase both the physical size and ripple current rating. This can be advantageous when working on older hardware as your capacitors will fit better.

Physical Size

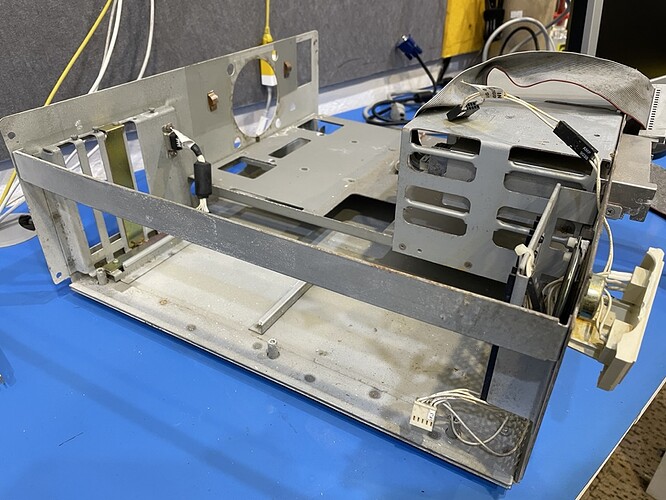

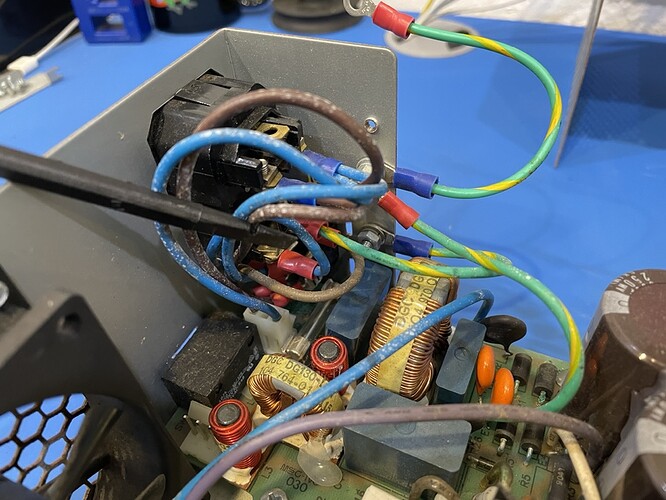

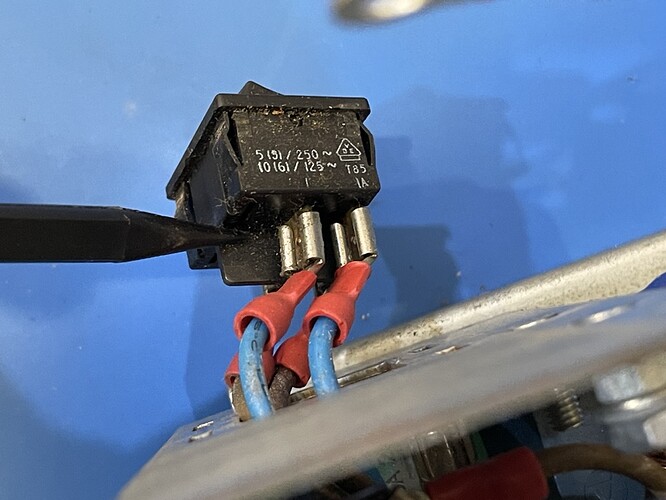

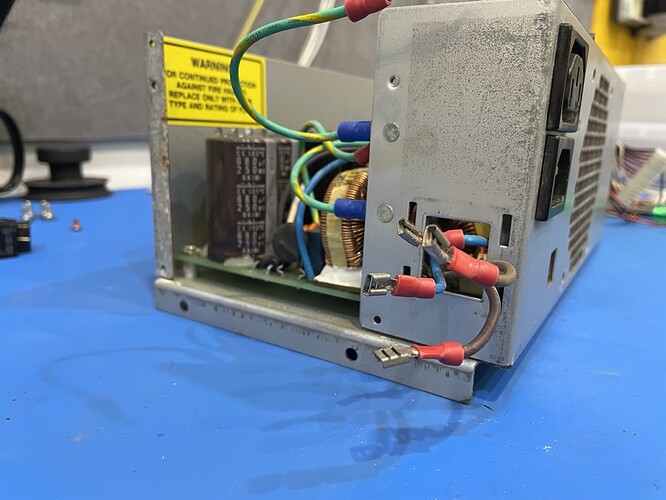

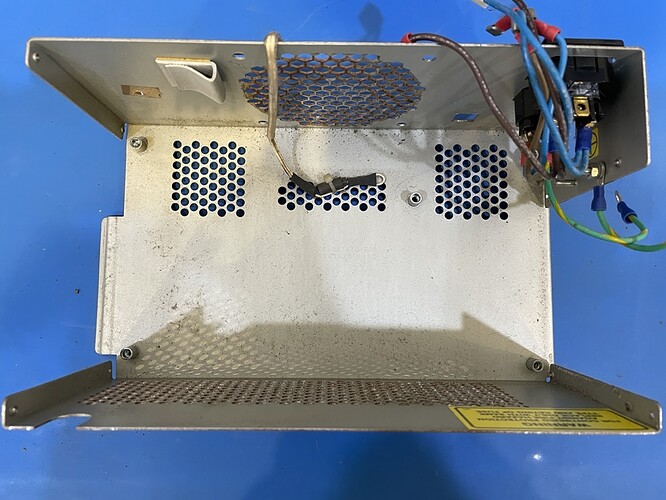

Keep an eye on the clearance, for example this power supply has plenty of height but not much width for the capacitors. The lead (leg) spacing on the capacitors should also be matched where possible.

Ripple Current Rating / ESR

Keep the ripple current rating as high as possible and ESR as low as possible. The two usually go hand-in-hand. Always check the datasheet and compare between brands. Low ESR/high ripple capacitors are usually more expensive, but picking from general-use capacitors will result in a hot running capacitor with shortened life span. Even worse, it’ll probably be operating out of range when compared to the circuit designers specifications.

Anyone with more on the physics is welcome to chime in, especially since I’m a botanist by trade

Temperature

You should always keep this the same or higher than the capacitors you are replacing.

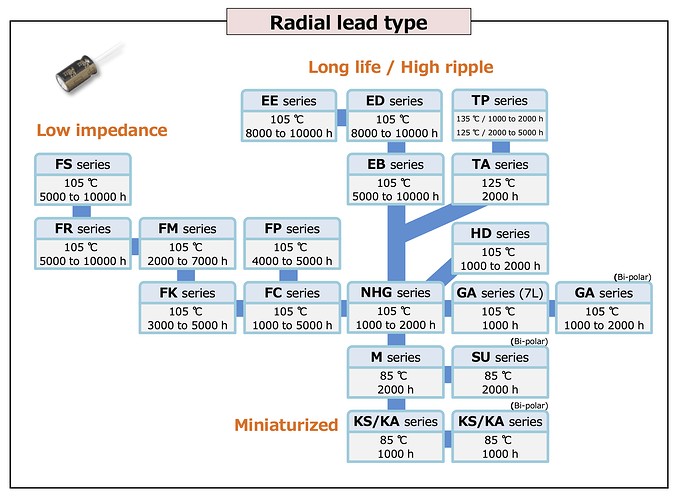

Here is a screen cap of Panasonic’s capacitor flow chart. For this project I would probably want to use capacitors in the FM, FR or FS series. I’ve gone the Rubycon route though, so we’ll have a look at their flow chart.

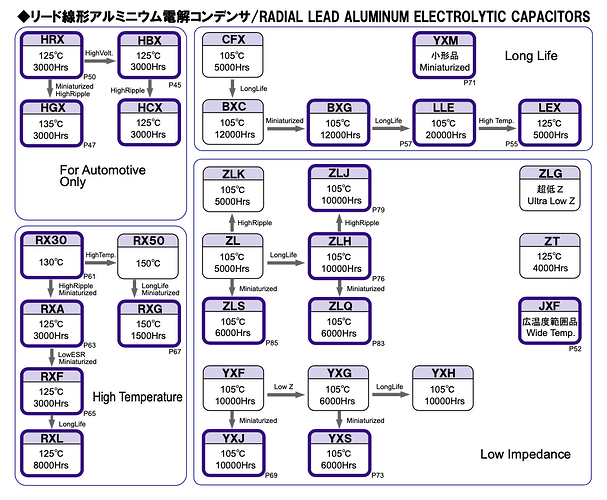

The lower right quadrant is where our interests lie, the low impedance area. Remembering we are in the middle of a capacitor shortage, let’s look at what I’ve ordered and any notes:

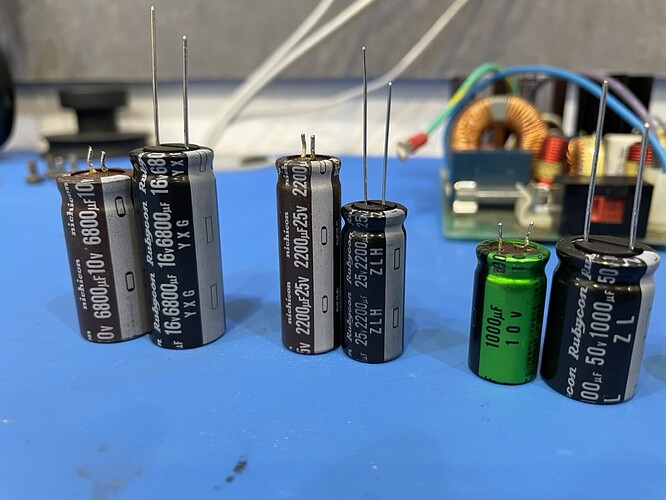

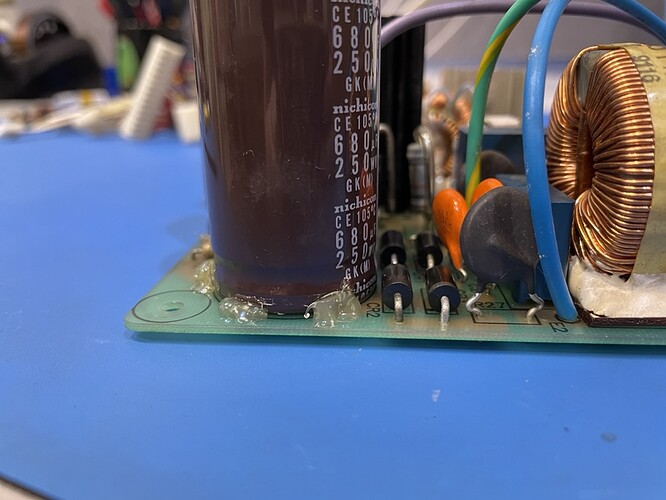

6800uF - Rubycon YXG Series

Low impedance

10V to 16V upgrade

5mm taller, plenty of clearance in the PSU case

2200uF - Rubycon ZLH Series

Miniaturised, long life, low impedance

Specs are the same - no changes

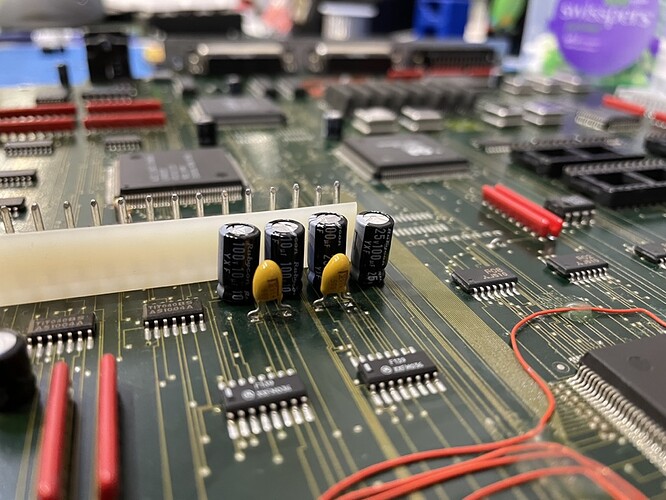

1000uF - Rubycon ZL Series

High ripple current, low impedance

Lead spacing from 5mm to 7.5mm

Width from 12mm to 16mm

10V to 50V upgrade

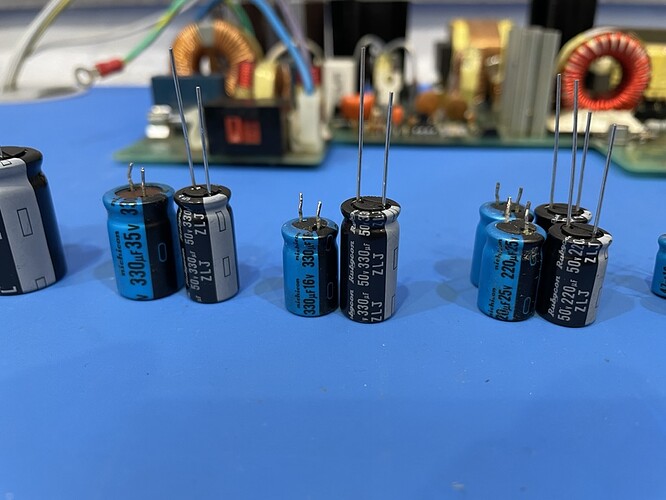

330uF - Rubycon ZLJ Series

High ripple current, long life, low impedance

35V to 50V and a 10V to 50V upgrade

Taller but plenty of clearance

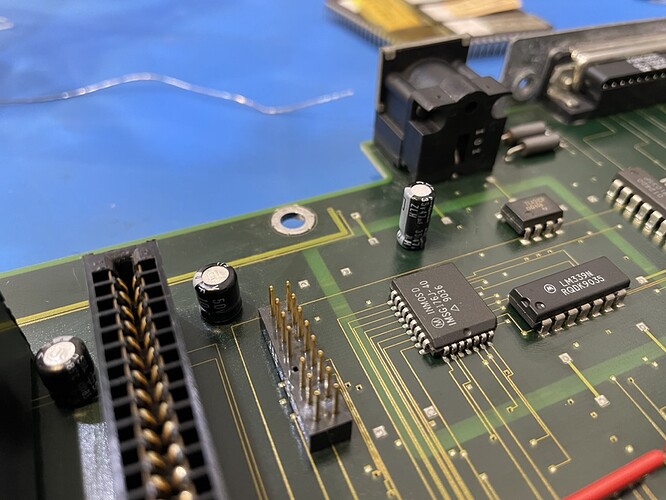

220uF - Rubycon ZLJ Series

High ripple current, long life, low impedance

25V to 50V upgrade

47uF - Rubycon ZLJ Series

High ripple current, long life, low impedance

Leg size 2mm - will need to bend to fit 5mm lead spacing

Width reduction - 6mm to 5mm

16V to 35V upgrade

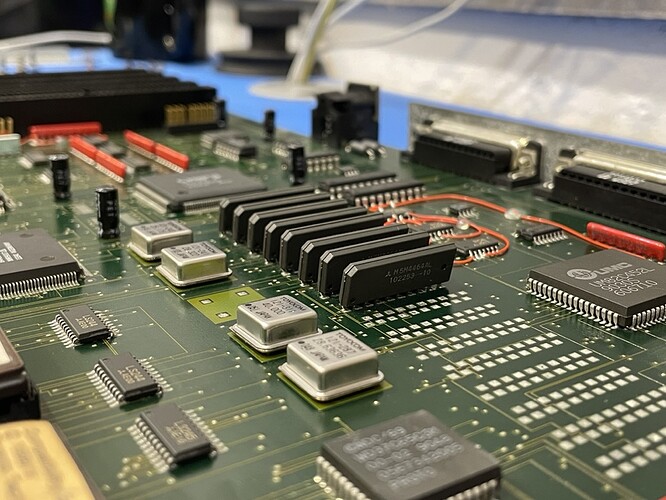

Now some of these upgrades are fairly big jumps for the voltages, it goes to show how far capacitor tech has advanced when you get some of the more reputable brands. You can see the recurrence of low impedance and high ripple current on most of the capacitors though. For reference, we’re mostly pulling out Nichicons and they are well past their service life.

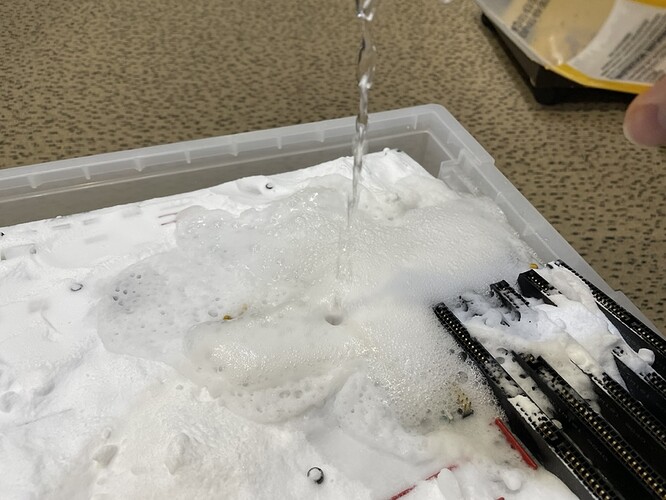

For now, we wait for the capacitors to arrive, they should be here by next weekend. In the meanwhile I’ll be:

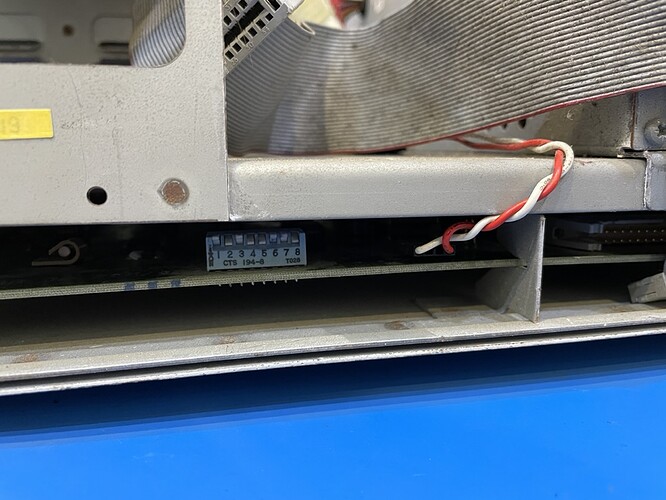

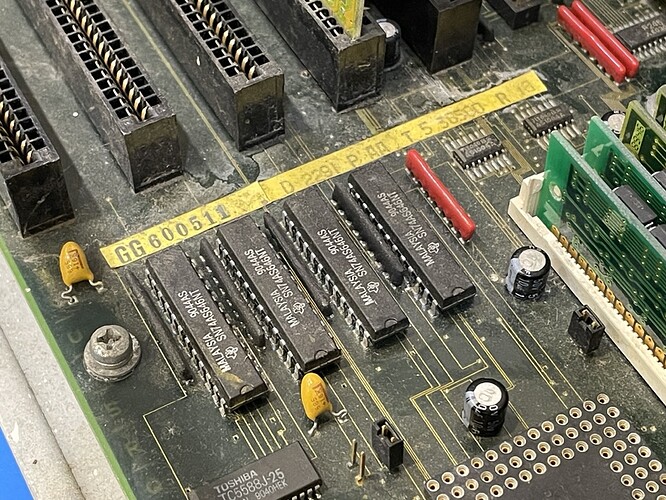

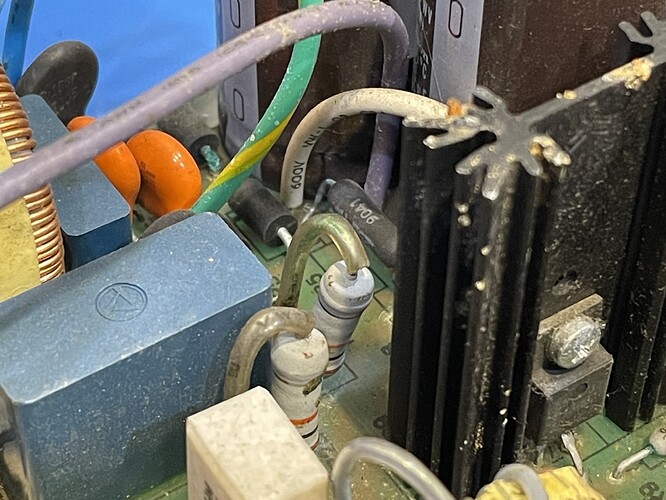

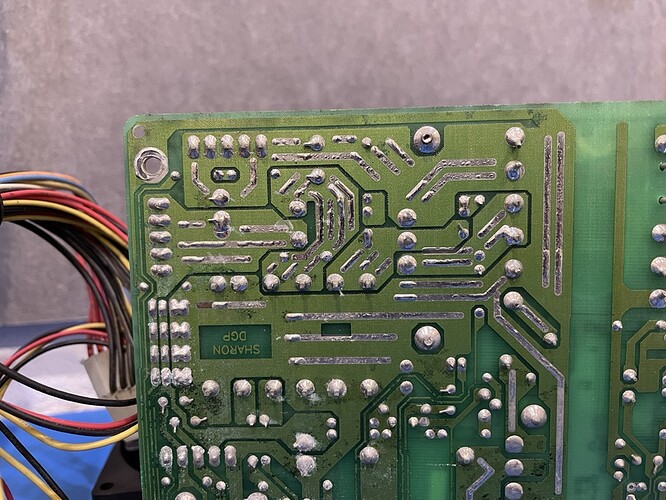

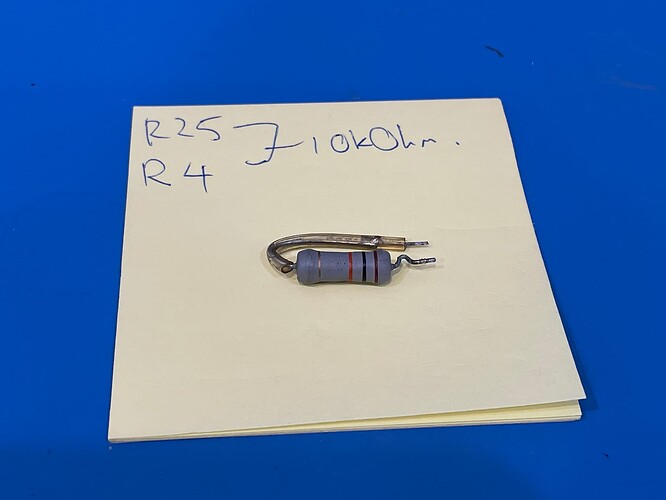

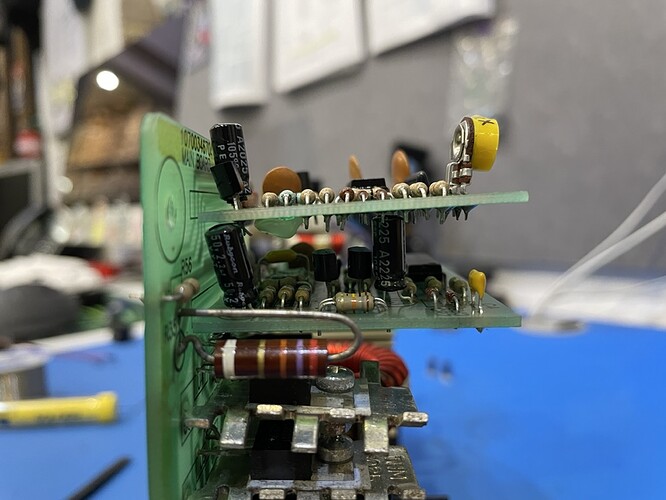

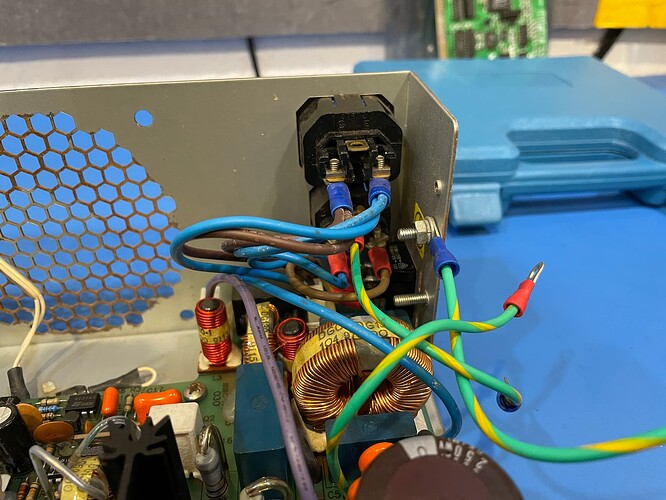

- Removing the resistors pictured above and cleaning inside the plastic protective tube.

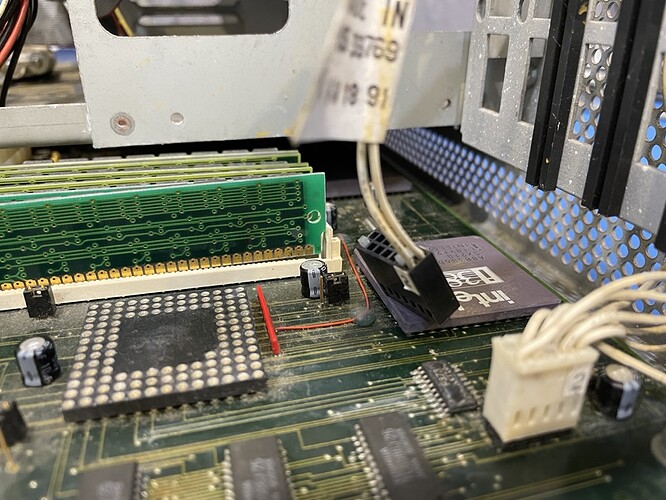

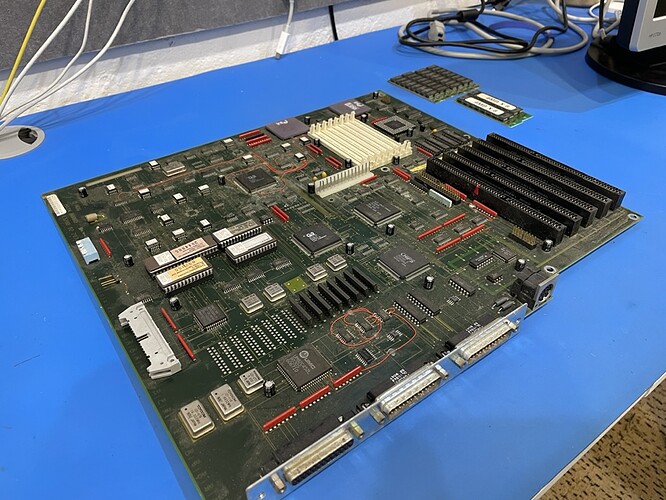

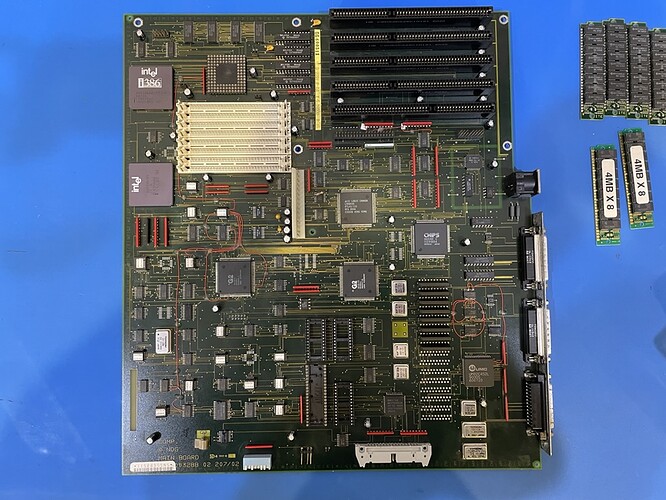

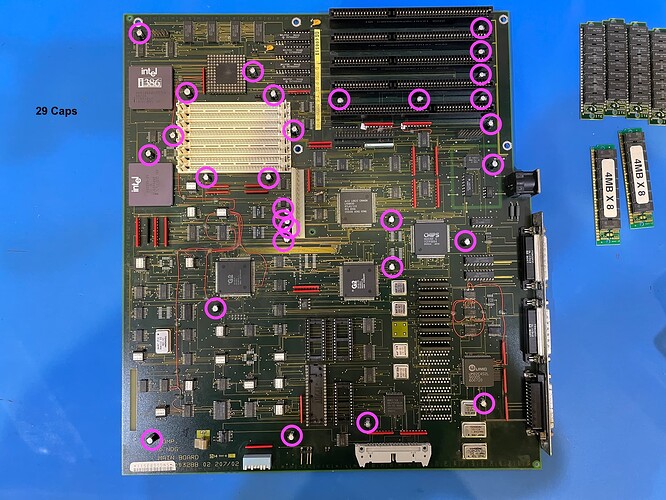

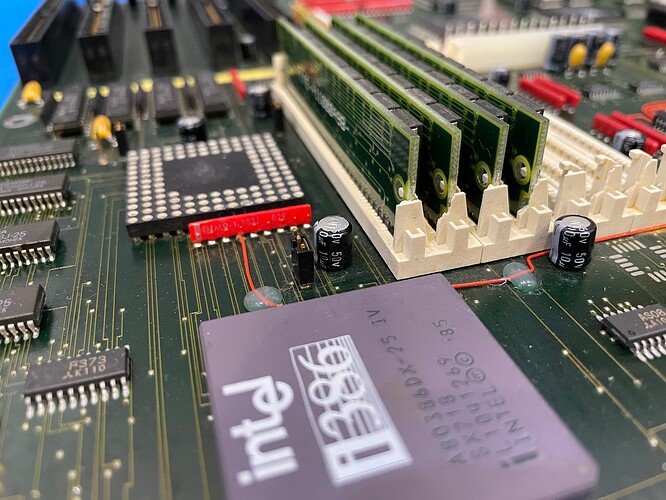

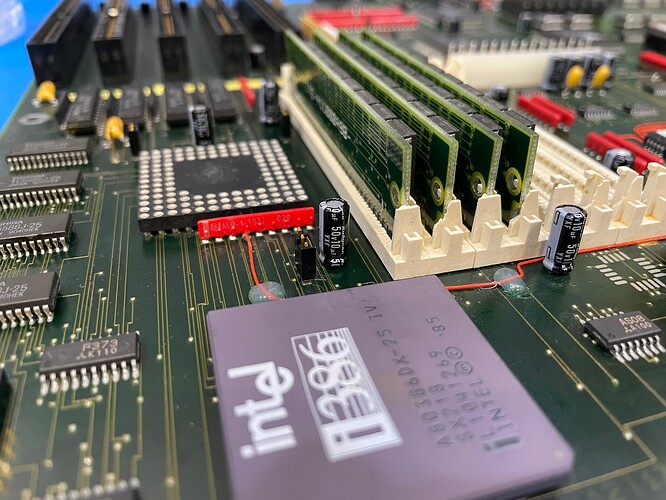

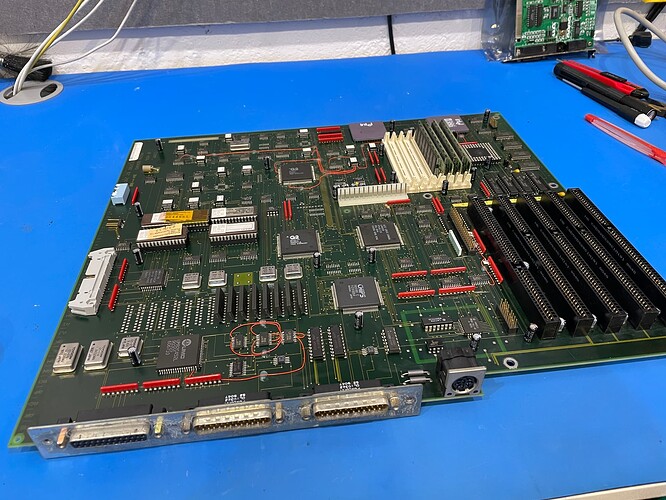

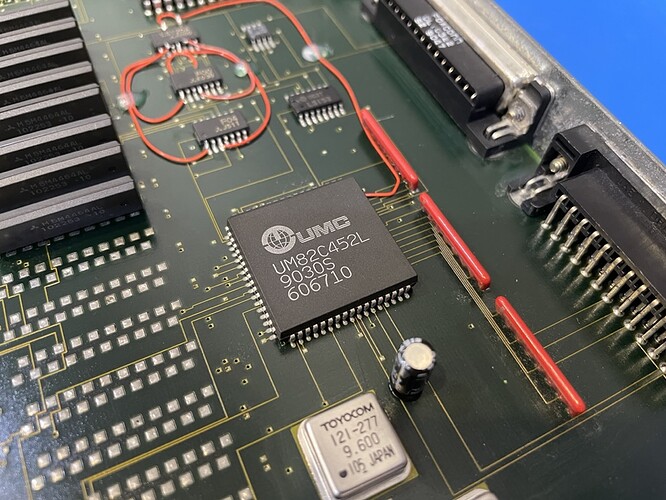

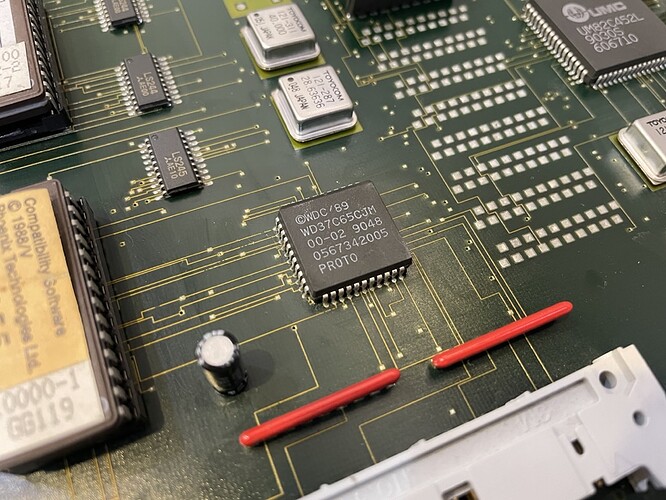

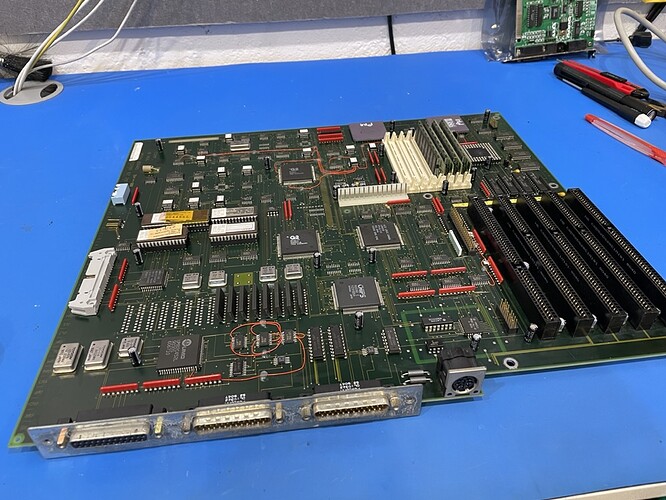

- Recapping the main board (maybe).

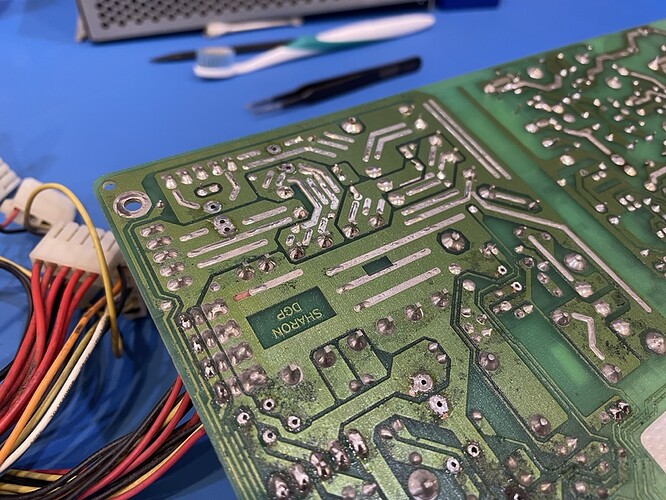

- Perform preventative maintenance on the Audio Drive ES688 with @ShaneMcRetro.

I hope the information above helps give an understanding of why we want low ESR, low impedance, high ripple current rating capacitors for the power supply circuit. Remember that this is my first dedicated power supply repair, I’m usually doing work on DC circuits. I’m hopeful we get a different result the next time it is connected to power. Until next update!

![]()