So, during October, I’m going to try restoring an Applix1616 to working condition. The system came into my possession from a Canberra local that was clearing stuff out of his house and offered it up to people at the local makerspace (Make Hack Void). He did not remember how it came into his possession or from whom. Of course, I snapped it up.

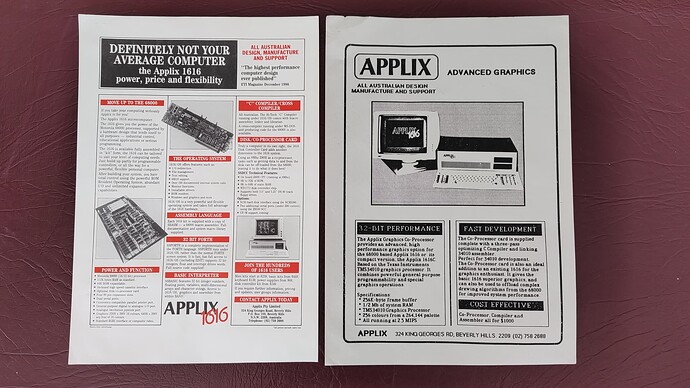

The Applix1616 was an Australian kit computer with a Motorola MC68000 CPU from 1986, made by Applix Pty Ltd in NSW. Applix was started by Paul Berger and Andrew Morton (aka akpm, who later became a maintainer of the Linux kernel). The design for the machine, plus some articles on construction and testing, appeared in Electronics Today International with a series of articles starting in December 1986.

If you want to read more on this, here’s some links:

- Wikipedia: Applix 1616 - Wikipedia

- Hackaday.io Applix1616 documentation project: Applix 1616 Documentation | Hackaday.io (have applied to this project as another place to upload scans/ROMS/files).

- Eric Lindsay’s Applix1616 page: Andrew Morton's Applix 1616 DIY Motorola 68000 multitasking computers

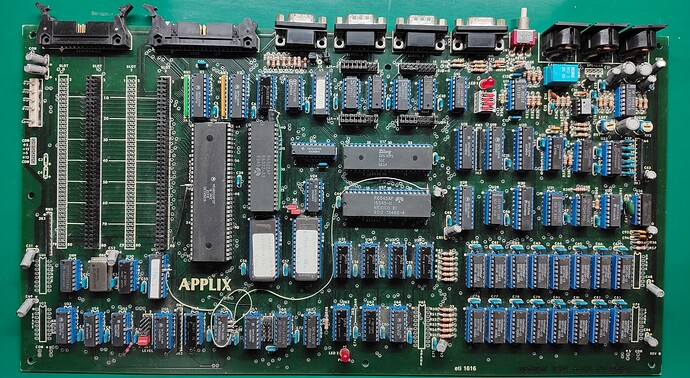

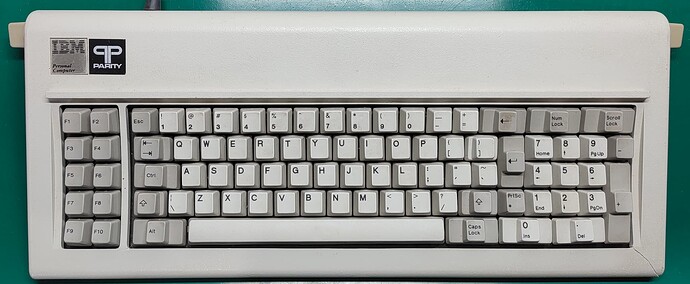

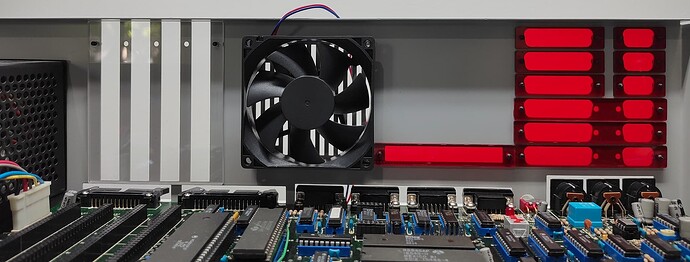

Below is the state of the machine when I received it.

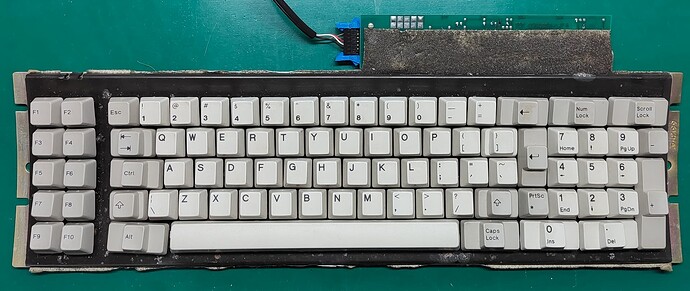

Front:

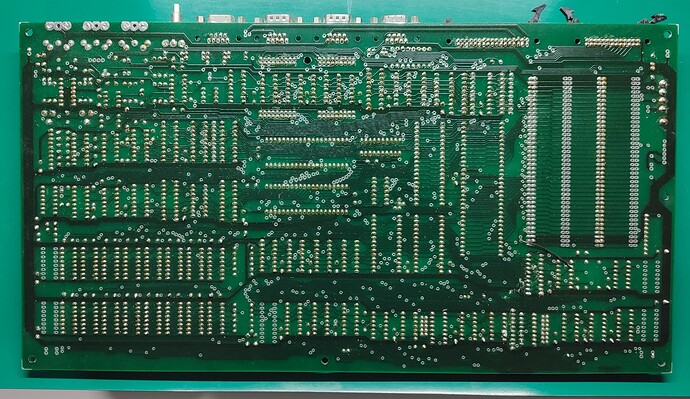

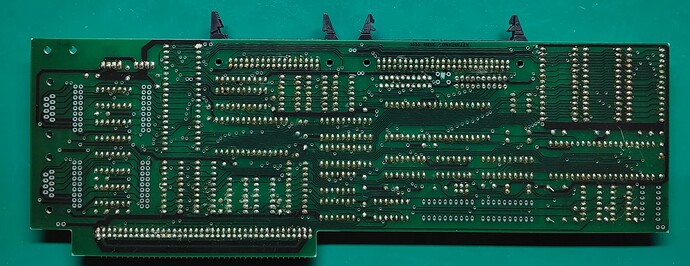

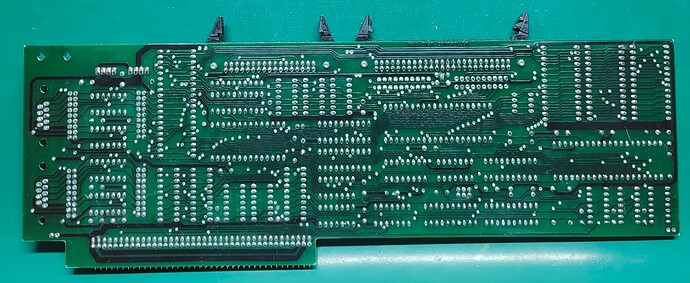

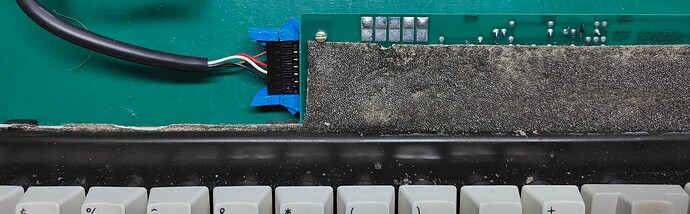

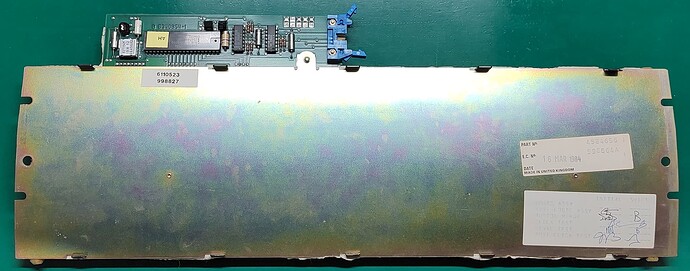

Back:

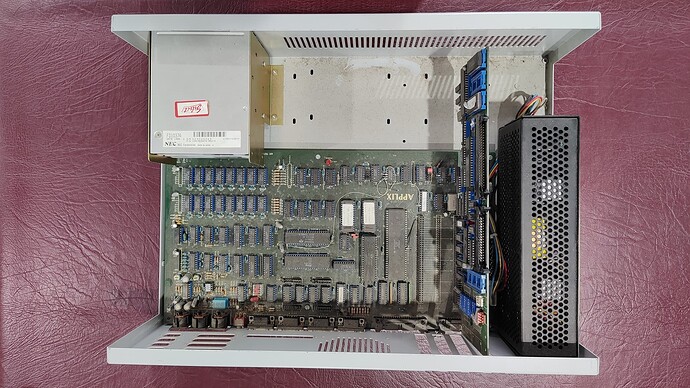

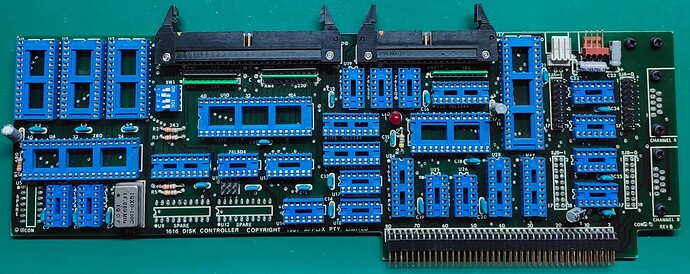

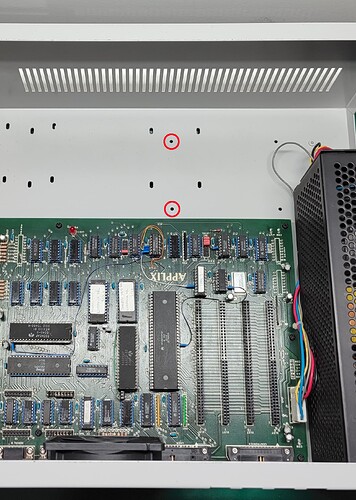

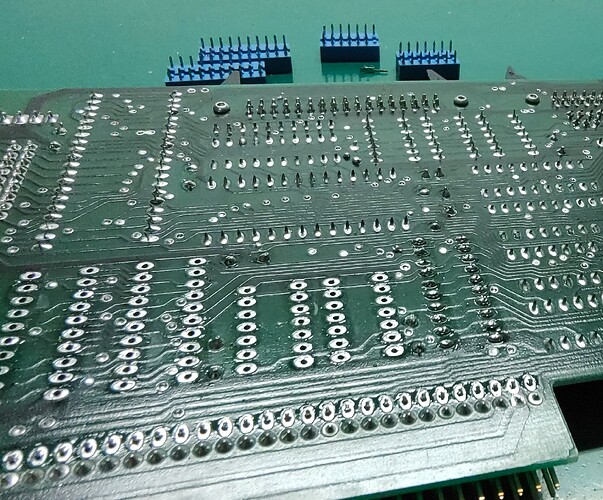

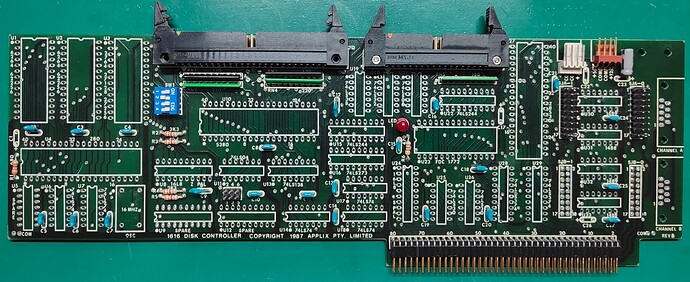

Inside, with one Disk IO Controller installed:

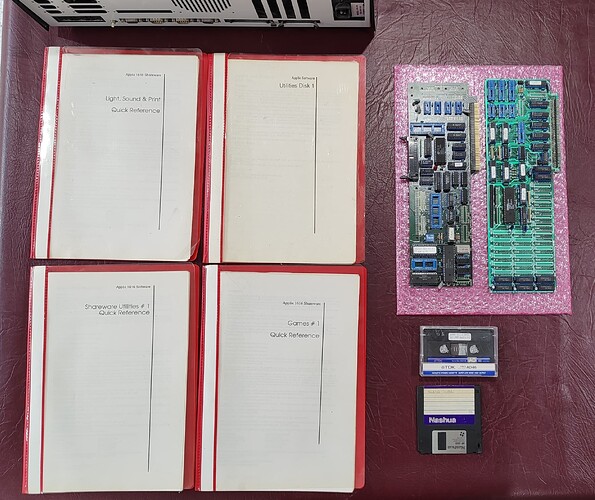

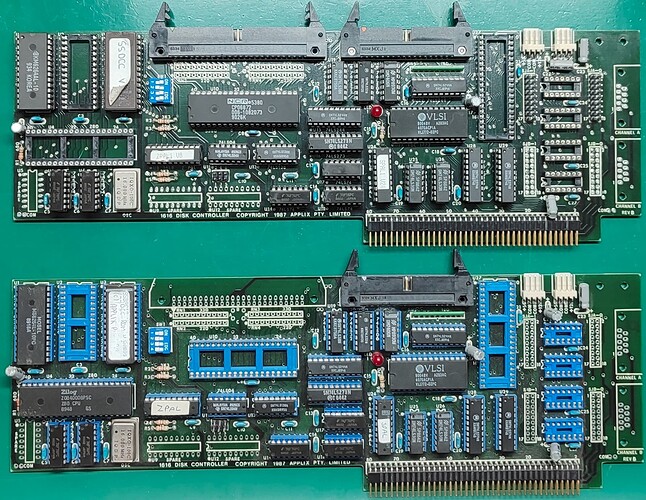

Manuals/Disks, plus the 2 extra cards:

Since then, I received a few more related paper docs that the previous owner found.

Ad copy:

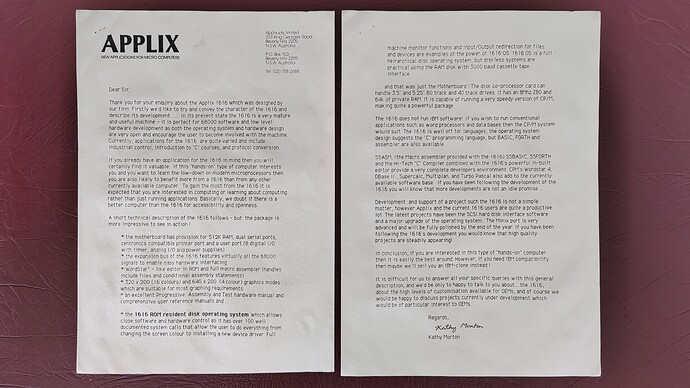

System enquiry response:

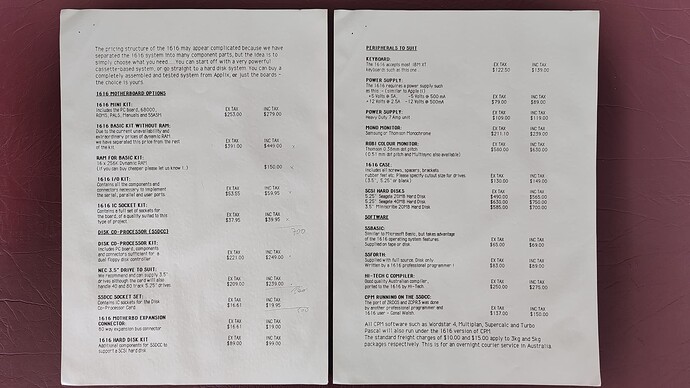

Price list:

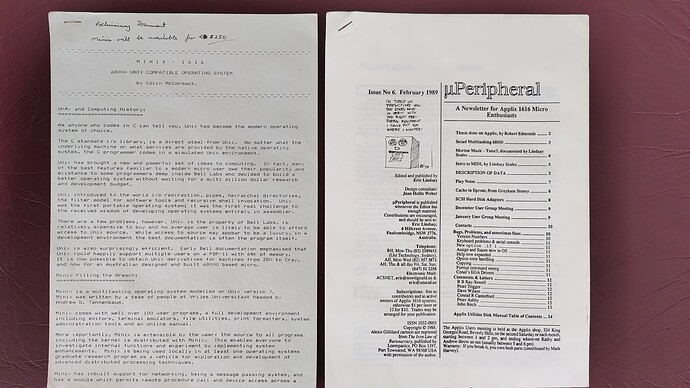

Copy of preliminary Minix - 1616 document, along with a copy of uPeripheral (Applix 1616 users newsletter):

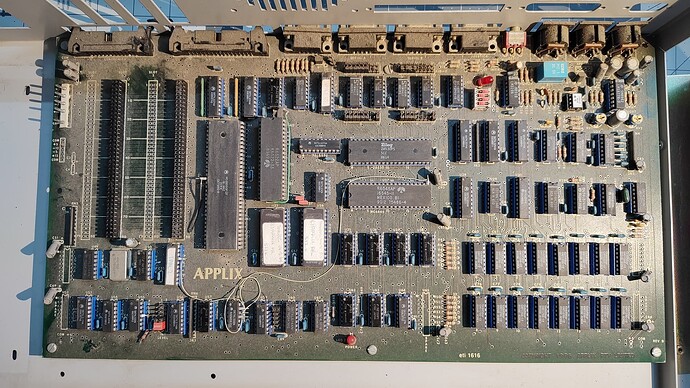

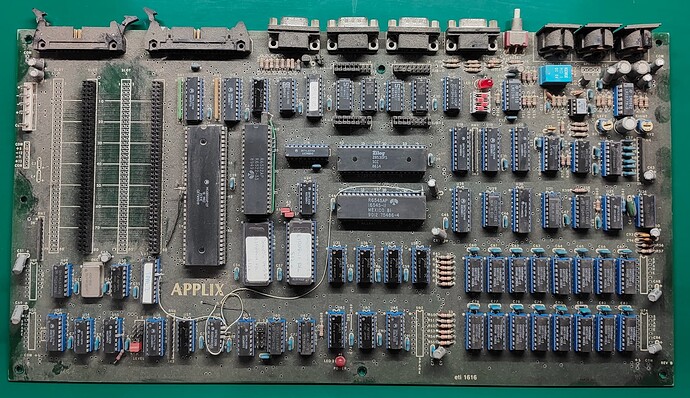

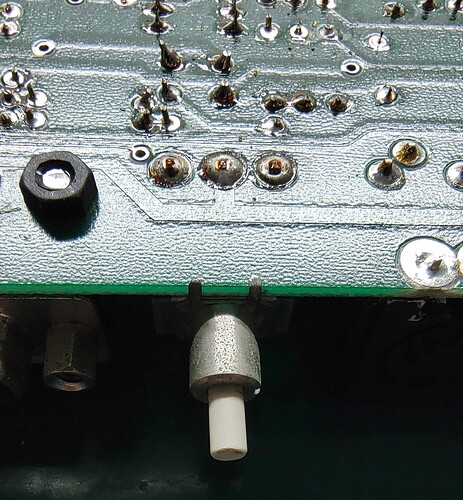

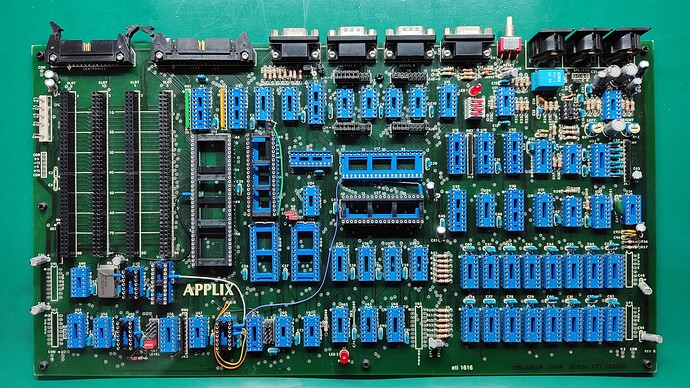

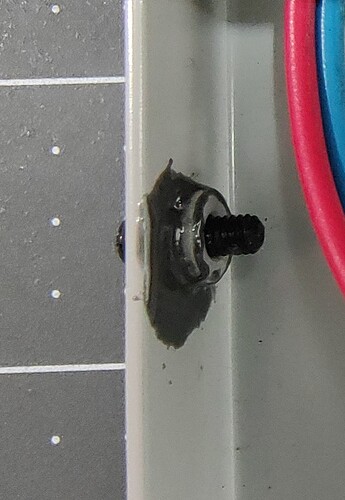

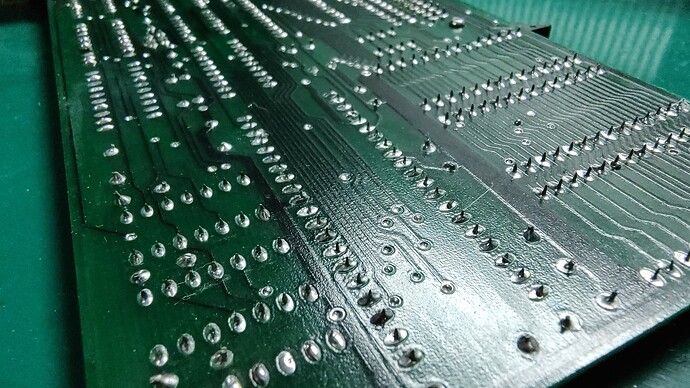

Since then, I have disassembled the machine from its case and cleaned the tops of all the chips on the mainboard. This was so I can document all the modifications (aka bodge wires) that have been done to the base motherboard, plus figure out what I might need as part of the restoration process (ie: to avoid delivery delays where possible). I also checked for any corrosion, as I wasn’t going to wait around till October to treat corrosion if it was just going to get worse. Fortunately there are no batteries anywhere in this machine.

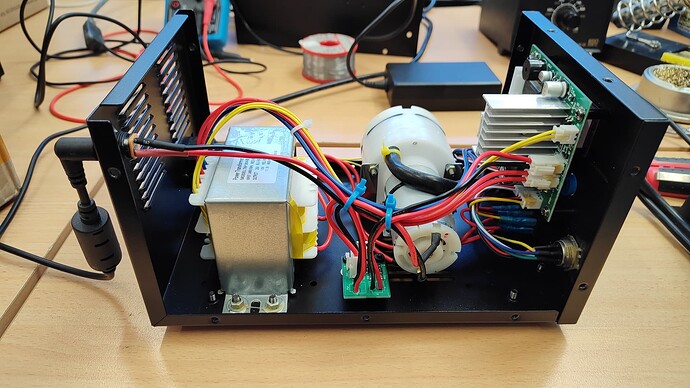

Note that I have not tested the power supply, nor have I attempted to power up the machine or test the floppy drives. No other work has been done.

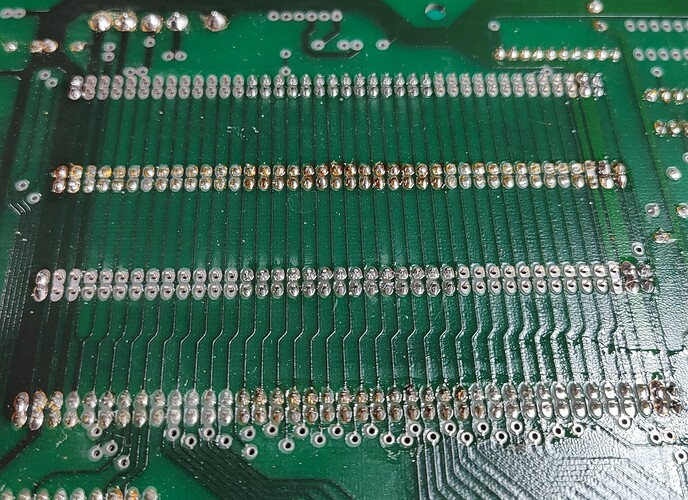

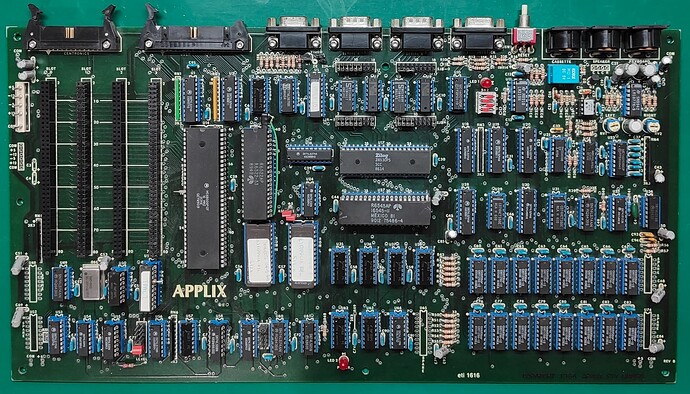

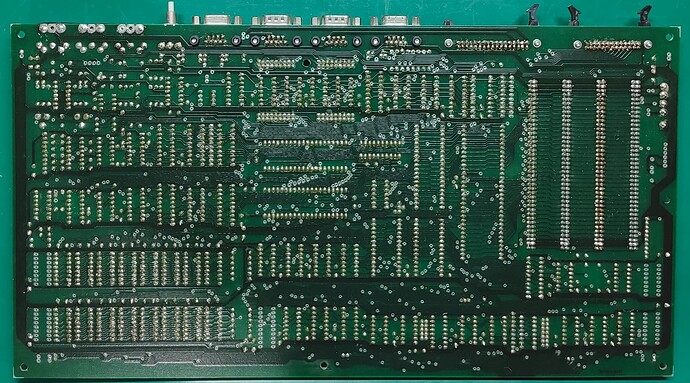

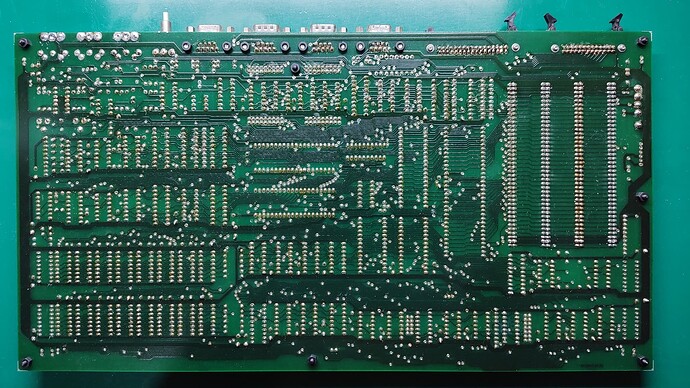

Motherboard with the chip tops cleaned:

Rough plan for October (what I’m setting out to achieve and document here):

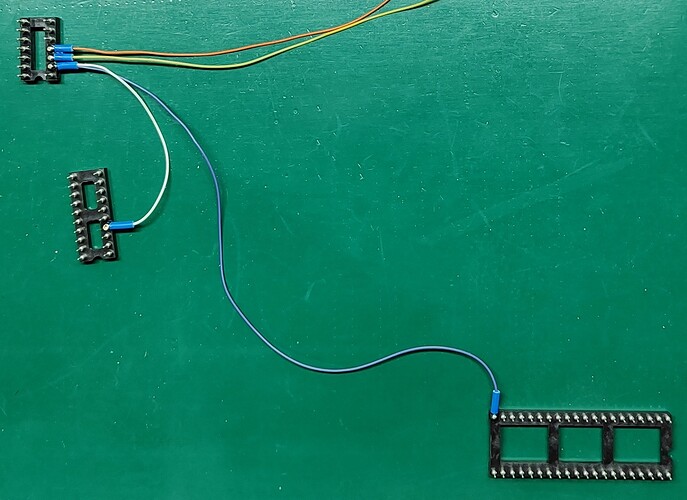

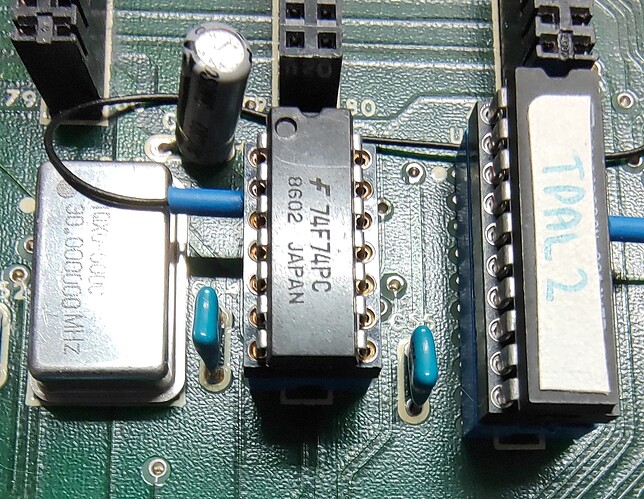

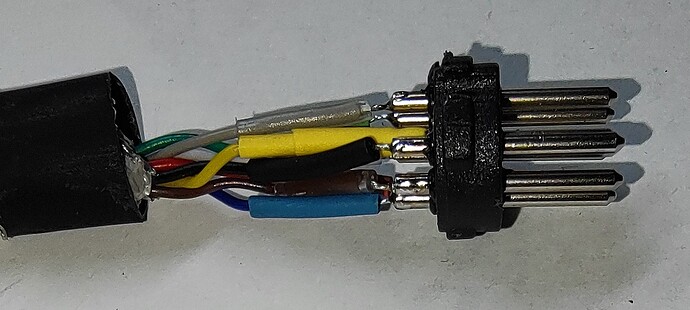

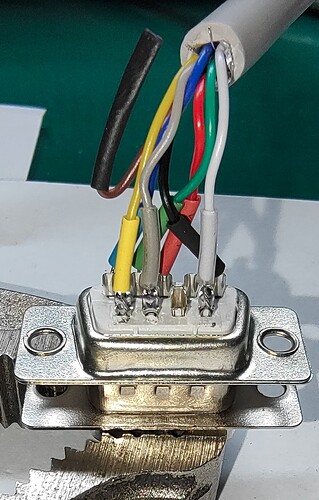

- Document fully the bodge wires on this machine and try to figure out the reason they’re present (eg: broken traces, circuitry revision, upgrades, etc).

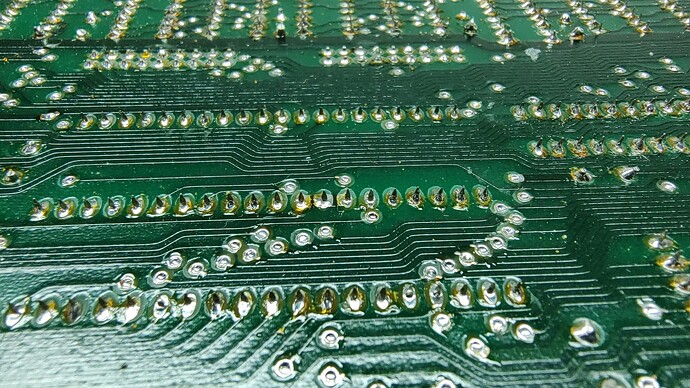

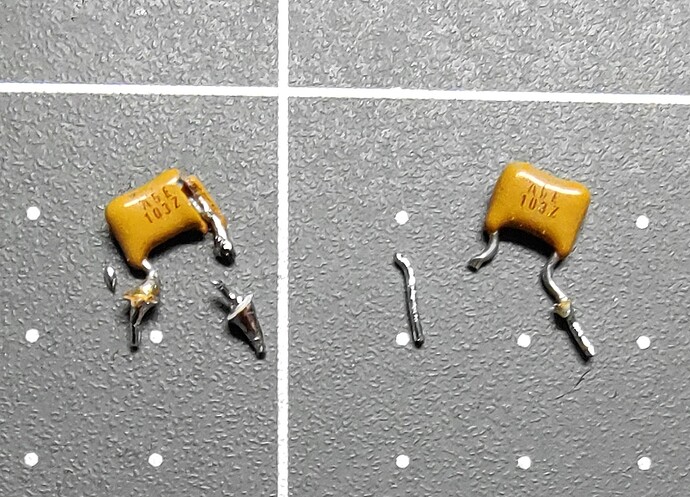

- Clean the board, plus remove all chips and current bodge wires from the board. Check for any bad joints, etc.

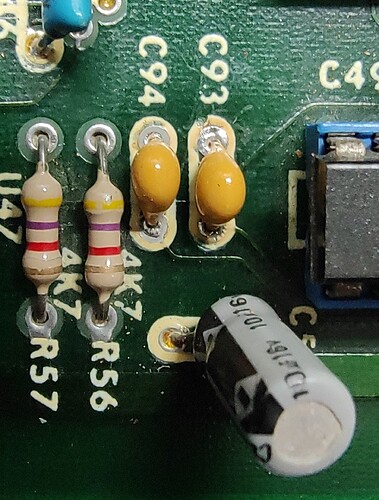

- Remove/test/replace the electrolytic capacitors on the mainboard.

- Confirm separate operation of the power supply and restore if possible. Will use an ATX break-out board if this delays anything. The mainboard requires +12V, +5V, -12V and -5V, which the break-out board I have provides.

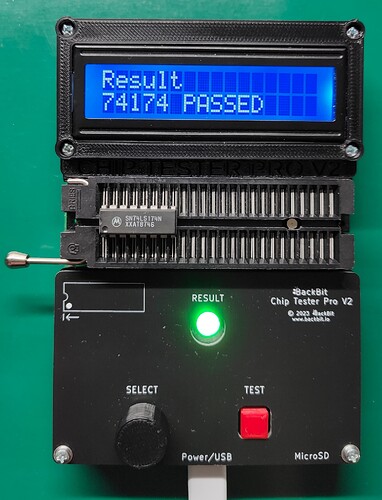

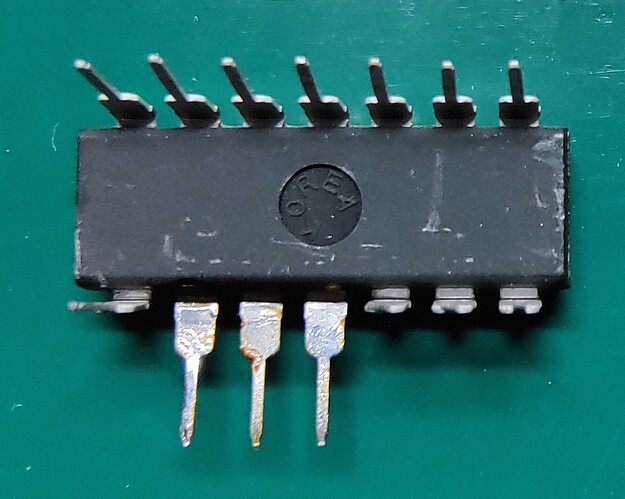

- Where practical, test all chips on the board (using a Chip Tester Pro from BackBit.io). This will definitely not include the MC68000 as the Chip Tester doesn’t support it.

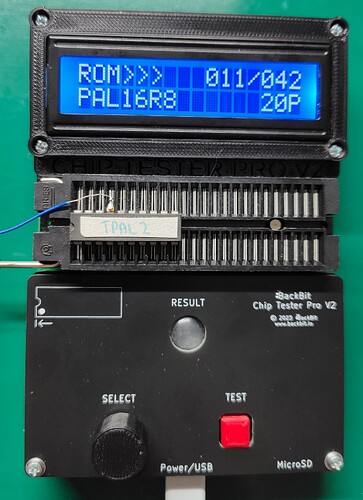

- Take ROM images and PAL/GAL images (where possible) from the machine for archival purposes using the Chip Tester Pro.

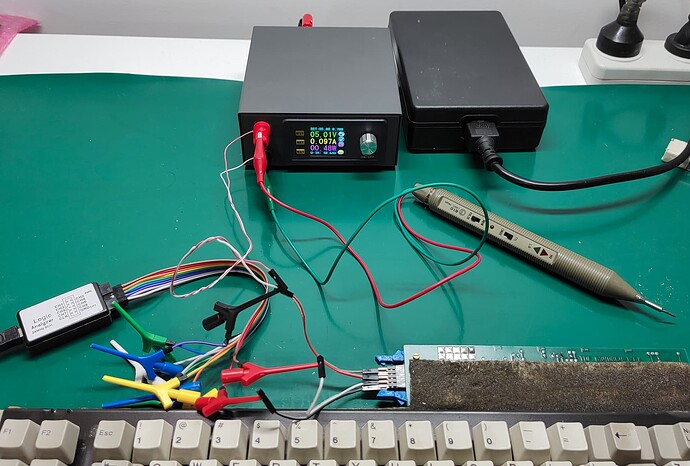

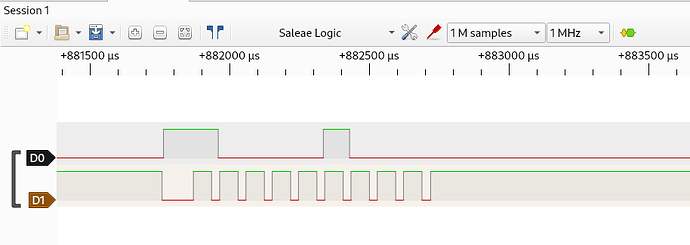

- Follow the build and test process documented in the “ETI project 1616 Hardware and Construction-Manual” (available on Eric Lindsay’s site, plus from the Hackaday.io Applix1616 Documentation project), which guides you through what chips to insert where, and what signals to look for, etc.

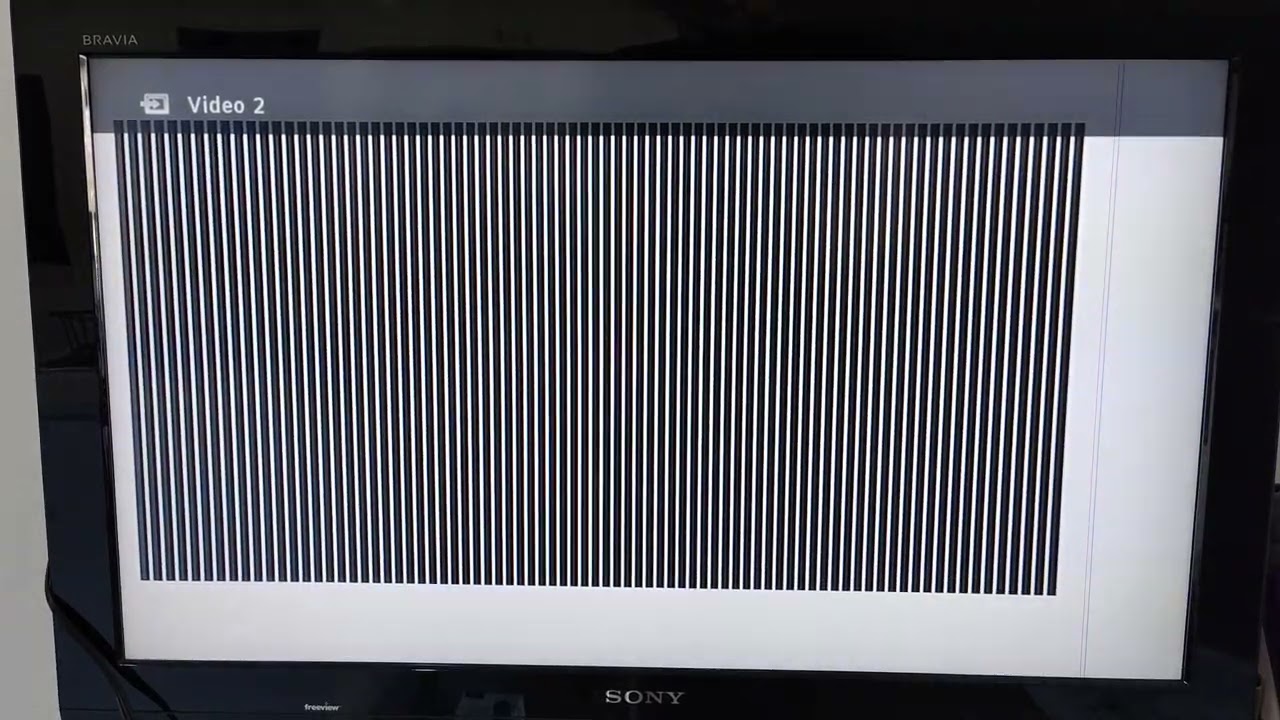

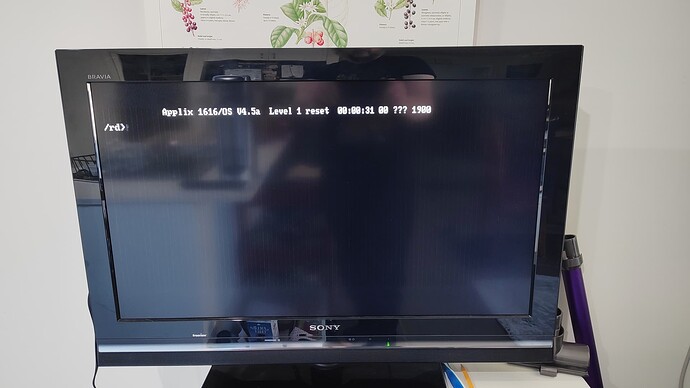

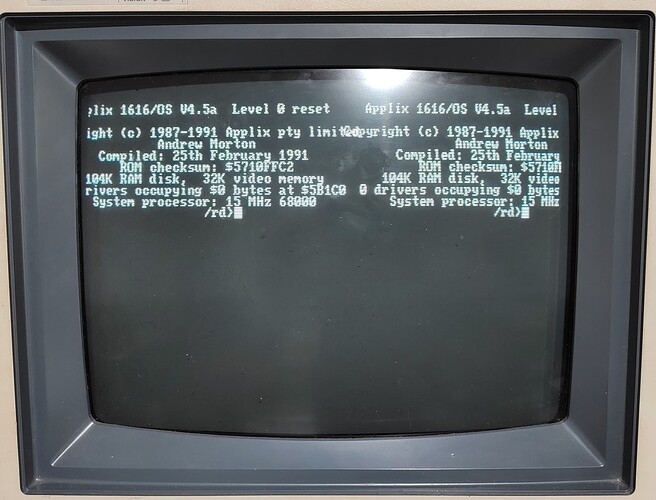

- Confirm working operation (OS is in ROM).

- Scan all the paper documents that came with the machine for base level archival purposes.

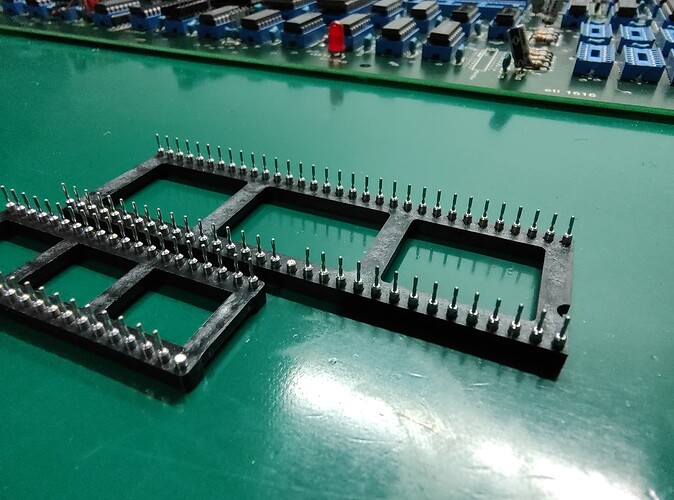

FWIW: When reinstalling chips that currently have bodge wires directly attached to lifted pins, where possible I will install them in machine sockets and tap the pin off separately, unless they can be safely pulled from an existing trace or have been confirmed that they aren’t needed (eg: fixing a broken trace/via). This idea is inspired by an existing mod on the machine, which adds a bodge wire and a resistor pull-up pack to a machine socket under the R6522AP, located to the right of the the MC68000. Fortunately all the IC pins that have been lifted to have bodge wires attached are intact.

Bonuses if I can get them:

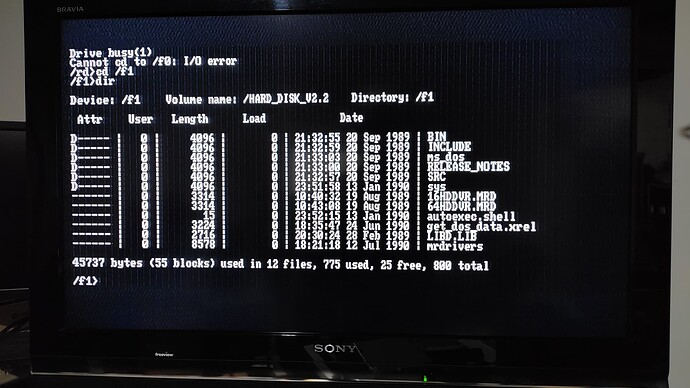

- Document, test and confirm operation of the at least one of the Disk Controller boards, and clean/test the NEC floppy drives. If possible, get ZR-DOS working on the Disk Controller (depends what is on the disks and in ROM).

- Document, test and confirm operation of the RAM Expansion board.

- Add a 3rd Expansion socket to the mainboard (currently 2 of 4 are populated).

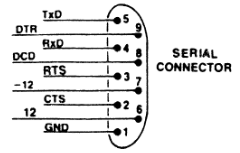

- Populate extra parts on at least one of the Disk Controller boards to enable the 2 extra serial ports.

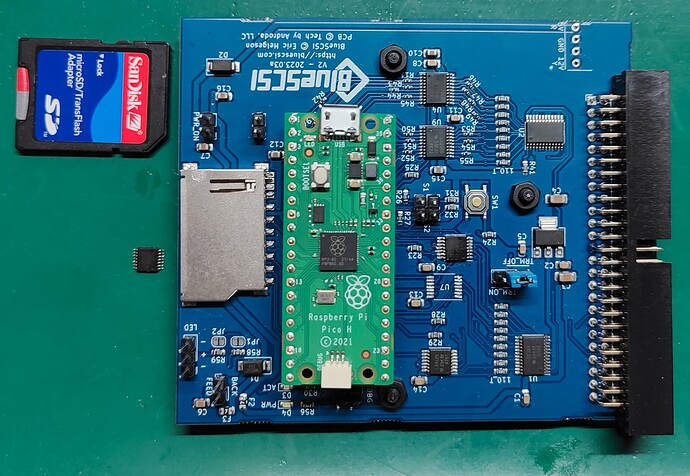

- Get a working SCSI hard disk set up (using a BlueSCSI V2).

- Extract data from the cassette tape and disk that came with the machine.

- if possible, update the OS in ROM to the last revision known (V4.7a).

FWIW: The Disk Controller has a Z80 on it that can run a port of ZR-DOS (passing the UI back to the MC68000), effectively allowing the machine to offload disk operations from the MC68000. The Disk Controller also has a SCSI bus, but this too is hooked to the Z80, so disk access using that SCSI controller is slow, but apparently possible via ZR-DOS. The RAM Expansion board has a SCSI controller directly mapped to the MC68000 bus, so I’ll be planning to use that SCSI bus where possible.

Note: I’ve documented the above state of the machine, as I don’t want to claim what I’ve done already as part of the RetroChallenge work. It’s not a huge amount, but it’s not wholly insignificant.