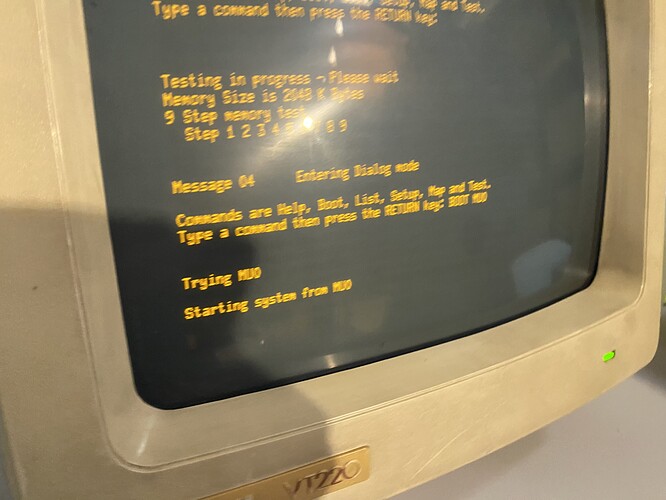

This is a stub for the restoration works on the TK70 Digital 293mb tape drive

The TK70 Tape drive connects to a Digital M7559 via a 26 PIN flat connector interface.

Tape drives enumerate as MU0: on Micro PDP and MUA0: drives on MicroVAX systems.

The DEC Datacasettes have tape wrapped around a single spindle with a plastic “leader” that sits at the very opening of the cassette/cartridge.

When the tape is inserted into the drive, the drive opens the access panel to the tape cassette/cartridge.

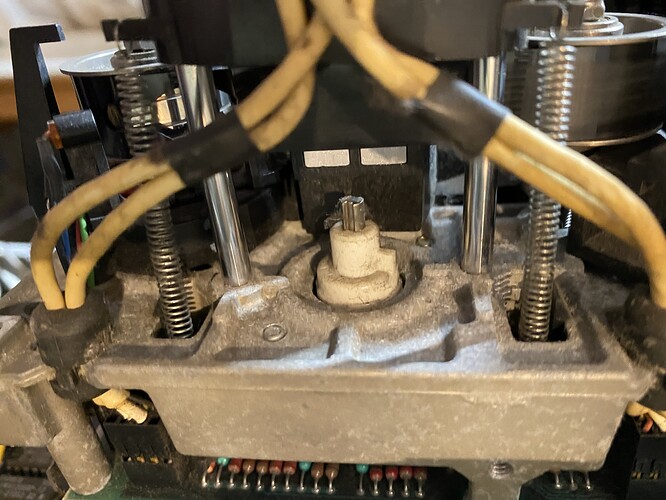

When the gate (below the tape) is closed, this forces the gear spindle upwards and engages from the base of the drive and pushes the spindle vertically into the cassette cartridge. This process unlocks the tape spindle which is normally locked in position when natively lowered when not inserted into a drive. This prevents the tape from becoming loose and non-tensioned in transit.

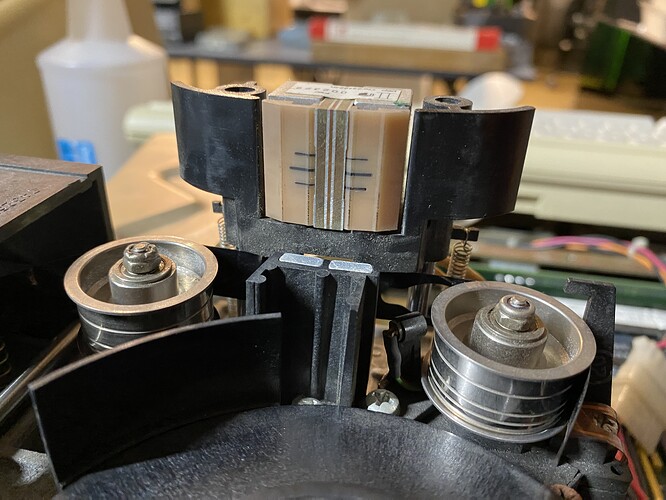

When the unit loads, a secondary plastic leader in the drive hooks onto the tape leader and pulls the tape into the drive - across a rather large magnetic head unit which is capable of raising and lowering electronically for alignment, it is held down by two springs.

There is a number of holes punched into the tape so that the drive can ascertain the start and end of the tape. These holes are found by an infrared light sensor to the right of the head assembly and is integrated.

After a long period of not using tapes the tape becomes magnetically and physically stuck at places in the cassette. This can cause the drive to error out blinking 3 lights.

Unspooling the tape to prepare it for use:

This is possible by loading the tape and allowing it to be captured and rolled onto the internal reel.

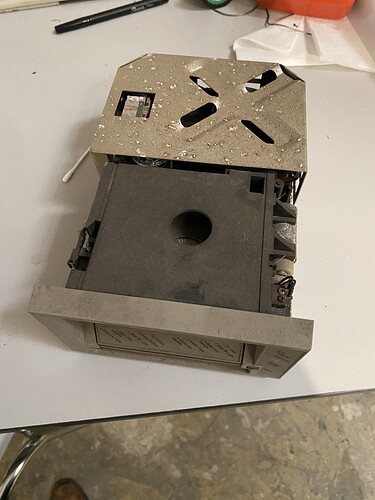

Once this is caught, turn off power to the drive and remove the internal reel capture cover.

Using an electric drill, slowly spool out the tape into the internal spindle.

Be wary of the end of the tape, going to far will rip the tape off the internal spindle in the cassette which is lightly glued on.

During our tests we accidentally did this, we had to carefully tape the tape back onto the spool. The tape drive can not retract the tape automatically if you go past the punched hole near the end of the tape, this is there to allow the drive to know it’s reached it’s limit and to stop.

IMPORTANT

You need to wind the tape back into the cartridge, this is possible via a thin long Phillips head through a hole in the underside of the drive.

The reason this is important, is that the tape needs to be exercised a few times.

In our efforts, when the drive tried to recoil into the cartridge off the drive spool, if it got stuck, the tape could fold in on itself and cause the tape to be loaded around the spool the incorrect direction (counter clockwise to the heads) and then the drive was unable to tension and put the tape back into the cartridge.

To clean the tape sensor clean the infrared lenses with compressed air or a qtip soaked in isopropyl 99.9% and allow to dry throughly.

To clean the head, you can remove 4 screws from the rear golden brassy coloured cover, and gently raise the head assembly which is held in by two springs. Clean with isopropyl 99.9% on a QTIP.